Efficient Forage Conservation and Storage

Top quality forage forms the basis of all high yielding diets in profitable dairy herds

Cutting Waste on Silage

Having grown top quality forage, can we reduce the losses in harvesting and storage to keep the feed value as close as possible to that of the growing

crop. It is time to revue our conservation techniques. Silage is expensive to grow and costly to make, be it grass, clover, wholecrop, forage maize

or crimped cereals. Having said that, great strides have been made in our ability to reduce losses during conservation with better machinery, more

effective new additives and improved clamping techniques.

Silage Additives

I have been heavily involved with silage and silage additives for over 35 years. Throughout that time I have seen literally hundreds of clamps per year. Over the years problems with silage have changed. Back then the problems were poorly fermented wet butyric silage resulting from excess nitrogen, low sugars, soil and slurry contamination and low dry matters.

Now the problems are more often down to heating, aerobic instability, moulding, shoulder and top surface waste mainly due to excessive wilting resulting in high dry matters combined with a lack of consolidation, delays in sheeting or air ingress due to inadequate sealing. All silage should be treated with an effective forage additive for maximum profitability. Your silage quality is important

But still the losses are there. There will always be some loss from fermentation during silage making, but the high levels of loss that we see on many commercial farm pits can be greatly reduced.

The majority of silage clamps have far more waste

than should be considered an acceptable loss

Waste can be highly visible in the form of slime layers, spoiled shoulders and mouldy silage forked off the pit and dumped, or where silage is rejected

by the cows and left in the trough. Waste can also be invisible and go completely un-recognised.

Waste can be highly visible in the form of slime layers, spoiled shoulders and mouldy silage forked off the pit and dumped, or where silage is rejected

by the cows and left in the trough. Waste can also be invisible and go completely un-recognised.

This can be due to high fermentation losses as a result of inefficient fermentation. It can also be due to heating behind the face due to lack of stability. Waste can also show up in reduced milk yields, poor fertility and increased concentrate feed rates.

Where an effective inoculant is used, a 1000 tonne silage clamp will typically contain around 50 tonnes extra silage due to the more efficient fermentation. The silage will also retain more of the feed value that was in the crop when it was cut, up to 50% more true protein, higher levels of sugars, more energy etc. In addition the silage will normally be more stable on the face, be eaten more readily by livestock and generally perform better with a higher feed value. This applies to all silage whether 1st cut, 2nd cut, 3rd cut, big bale, wholecrop or maize.

As a general rule using a silage inoculant to treat forage costs only 3p - 5p per cow per day to generate around 1.5 litres extra milk. That is around £10 - £20 clear profit for every £1 spent before taking account of the extra 50 tonnes silage in the clamp.

The majority of the farms that I am involved with, do use a forage additive, yet many others don't, or only treat some of the forage. I am only too aware of the constant battle with cash flow on dairy farms. Yet I find it a little odd that when the cost benefits which have been demonstrated time and time again are so great, some farmers decide to miss out on a significant contribution to bottom line profit.

Forage makes up more than half the diet. As a nutritionist I well know the problems of trying to ration cows with poorly conserved forage. In recent years I have concentrated heavily with some success, on finding ways of improving the dry matter intakes and feeding quality of forage crops and also in reducing conservation losses.

RWN has spent a number of years developing, trialling and testing a highly successful range of very advanced and very competitively priced forage additives. The Ultra-Sile Range of forage additives is well ahead of the game in giving a rapid, efficient fermentations together with greatly improved aerobic stability on high dry matter grass, wholecrop, maize and crimped cereals.

Most inoculants on the market are homo-fermentative and convert sugars directly to lactic acid,

rapidly and efficiently dropping the pH of the silage.

That's fine on silage between 15% and 25% dry matter. Above 25% dry matter there is a danger of

aerobic instability and heating behind the face caused by yeast and mould activity. If this happens then

lactic acid is broken down and the silage can mould with high resultant losses.

Most inoculants on the market are homo-fermentative and convert sugars directly to lactic acid,

rapidly and efficiently dropping the pH of the silage.

That's fine on silage between 15% and 25% dry matter. Above 25% dry matter there is a danger of

aerobic instability and heating behind the face caused by yeast and mould activity. If this happens then

lactic acid is broken down and the silage can mould with high resultant losses.

When clamping forages over 25% dry matter we recommend using a specialist additive suitable for higher dry matter material such as Ulra-Sile Dry, Ultra-Sile HiDri, Ultra-Sile Maize or Ultra-Sile Arable, which are suitable for use on higher dry matter material.

Attention to detail with clamp management can greatly reduce waste on most pits

Silage Clamp Sealing

A few points to consider: Whether or not an inoculant is used, efficient silage fermentations rely on the clamp being effectively sealed right from the start and there being no air present throughout the fermentation. Consolidation and effective sealing is all-important. As a guide if you can easily push your fingers into the silage deeper than the finger nail or first joint, then there is a danger of aerobic instability, especially on mature, long chopped silages over about 26% dry matter.

Roll layers no more than 6" inches (15cm) thick. Dual wheels are less effective since they halve the pressure when rolling. If possible use an additional tractor for rolling. Sheet immediately after filling. Make sure you have enough clamp space. Do not over fill clamps un-consolidated shoulders are a disaster. Plan your clamps so that the smallest possible face is open at anyone time and do use a shear grab.

Typically silages lose over 20% of the weight of the top metre during storage.  Black plastic is porous to air. It can let through up to 2 litres of oxygen per m2 / day. If the sheet is lifting in the wind, chances are it is sucking air into the clamp like a bellows.

Black plastic is porous to air. It can let through up to 2 litres of oxygen per m2 / day. If the sheet is lifting in the wind, chances are it is sucking air into the clamp like a bellows.

We are currently working with low oxygen transmission films to reduce oxygen ingress into silage pits. Effective air tight sealing of silage pits can also be ensured with the use of close weave protective nets together with the use of lorry tyre sidewalls to apply an even weight across the entire pit surface. Always side sheet and always double check that all the edges are sealed and the clamp really is air tight. Always use an effective additive.

If its worth putting in the pit its worth doing properly

Always use low oxygen transmission barrier sheets such as Passion Ag Yellow or Silostop Orange film. These genuine oxygen barrier films are many times better at keeping air out of the clamp than cheap clear polythene cling film type products or conventional black plastic silage sheets.

Always use an additive. RWN's Ultra-Sile Range of forage additives have been highly effective in improving both the efficiency of fermentation and the aerobic stability of silages. Treating all your grass silage, big bales, wholecrop and maize is an opportunity not to be missed. Check our Silage FAQ's page.

Use a protective net. A protective net over the plastic sheet, prevents

holes in the plastic keeping out air and water. Passion Ag

close weave protective nets are easy to handle and give

excellent protection. Close weave nets not only exclude sunlight protecting plastic sheets from UV light,

but also reduce air pressure changes and ingress of air into the clamp on windy sites especially where

conventional clear polythene or black plastic sheets are used .

.

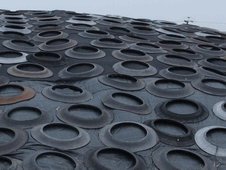

Always apply additional weight evenly over the clamp surface. Silage nets prevent holes in plastic sheets. They do not apply weight. Use lorry tyre sidewalls, rubber mats or car tyres to keep sheets and nets in close contact with the silage and to consolidate the surface layers of the silage clamp.

Summary

All silage clamps are subject to dry matter losses, however attention to detail in consolidating the silage, more effective sealing to exclude air together with the use of advanced new forage additives can dramatically cut losses and increase animal performance

It is essential that we continue to improve both the quality and the quantity of forage that we produce within the UK dairy industry

I cannot remember a time where there have been so many exciting new advances in forage crops, forage conservation, feeding and dairy nutrition open to dairy farmers. Taking full advantage of new technological advances really can bring rewards.

Contact Richard Webster for advice on making the most of maize