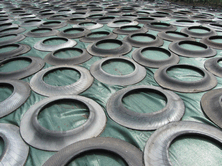

Lorry Tyre Sidewalls the best heavy covers for silage

Lorry tyre sidewalls offer the most effective solution for applying an even weight to the surface of silage. Ideally they should be laid over an oxygen barrier film and woven protective cover. Silage clamps need to be airtight. Silage dry matter and nutrient losses are greatly reduced in well-sealed clamps.

Is there waste and mould on top of your silage? Are the top layers warm? Lorry TyreSidewalls provide a cheap, effective means of applying weight to sheets and nets on top of silage clamps.

What is needed are heavy, secure clamp covers that don't move and are easy to handle. Woven protective nets alone

are not heavy enough and can lift in the wind drawing in air. Whilst Lorry Tyres Sidewalls or old car

tyres apply in excess of 13 kg/m2 silage

nets typically apply less than 0.33 kg/m2 to the silage clamp surface.

What is needed are heavy, secure clamp covers that don't move and are easy to handle. Woven protective nets alone

are not heavy enough and can lift in the wind drawing in air. Whilst Lorry Tyres Sidewalls or old car

tyres apply in excess of 13 kg/m2 silage

nets typically apply less than 0.33 kg/m2 to the silage clamp surface.

Old car tyres on silage pits are becoming a thing of the past. car tyres are dirty, labour intensive, a filthy job which everyone hates they no longer have a place on the modern dairy farm.

Silage clamps need to be completely airtight to minimise losses

For optimum sealing we recommend using Passion Ag or Silostop low transmission oxygen barrier film, on the top and sides of the silage clamp. Cover this with a conventional black plastic sheet and woven protective silage covers to guard against any holes. Then cover with RWN Lorry Tyre Sidewalls, to apply an even weight across the whole clamp surface.

We find this system to be the most consistently effective silage clamp covering system which has the potential to reduce dry matter losses and spoilage far more effectively than other clamp sealing systems.

Why Do We Get Top Waste on Silage Pits?

Cutting

waste and spoilage on silage pits is a great way to improve dairy farm profitability. Spoilage and top

waste is due to incomplete or delayed fermentation in the top layers of silage resulting from the presence

of oxygen during the early stages of the fermentation.

Oxygen can be present due to delayed sheeting, inadequate rolling, penetration of oxygen through conventional black or clear polythene sheets, or due to a lack of weight on the top sheets and nets resulting in air pockets under the sheet and a lack of consolidation in the top layers of silage.

Efficient silage fermentation is an anaerobic process which takes place only once there is no air present. The presence of air delays fermentation, massively increases dry matter and nutrient losses allowing breakdown of protein, sugars and loss of feed value as well as allowing rapid production of yeasts, moulds and other spoilage organisms.

The result of inadequate sealing often results in high dry matter losses, reduced feed value, wasted silage, slime layers, mycotoxin contamination, aerobic instability and heating on the face in the top metre of the pit. Lost feed value and increased concentrate use can result in increased costs annually of tens of thousands of pounds.

Prevention of Waste on Silage Clamps

It

is essential to consolidate well, seal as soon as filling is completed. Also a sheeting system should be used which

fully prevents the entry of oxygen. Sealing all sheet edges and protecting the sheets from damage.

Using low transmission oxygen barrier film with woven silage protective covers to prevent damage to the plastic film. This well researched system has dramatically reduced waste on silage pits both in scientific trials and on commercial farms.

However even with oxygen barrier film, for optimum results additional weight across the entire top surface of the clamp is highly beneficial. This acts to consolidate the surface layers on light fluffy dry forages and to keep the silage sheets in close contact with the surface of the silage in order to prevent air pockets.

Apply weight on top of silage sheets and nets

over the entire surface

RWN Lorry Tyre Sidewalls

RWN Lorry Tyre Sidewalls

We can supply inexpensive lorry tyre sidewalls or tyre rings made from lorry tyres, perfect for covering pits and silage clamps.

Lorry tyre sidewalls have been widely used for many years on silage pits in North America, Canada, Denmark, France, The Netherlands, Germany, and Scandinavia.

Lorry Tyre Sidewalls are approximately 1 metre diameter and weigh around 12 - 13 kgs. Each sidewall or tyre ring will cover 1 square metre of pit. The Lorry Tyre Sidewalls are strapped into bundles for ease of handling and are delivered on walking floor loads of 1900 to 2370 sidewalls. Each load will typically cover a 2000 m2 silage pit.

Since bundles can easily be reloaded onto farm trailers, some farmers split loads with a neighbour. Lorry Tyre Sidewalls are very easy to handle and will quickly cover a silage clamp.

Covering silage sheets and protective silage nets with additional weights improves the feed value of the top layers of silage as well as reducing dry matter losses, spoilage and heating. This is an effective means of reducing purchased feed costs.

Tyre Sidewalls help maximise energy for Dairy Cows and for AD Plants

Lorry Tyre Sidewalls are ideal for AD plants. Good consolidation, sealing and applying additional weight to the surface of silage, maize and wholecrop feedstock clamps will minimise losses of dry matter and fermentable energy, and maximise biogas yields for anaerobic digestion.

Whilst heavy green woven nets protect sheets

they do not apply significant weight

Old

car tyres have been used for many years but on many farms after 30 to 40 years they are past well past

their sell by date, are losing wires and need to be replaced urgently.

Old

car tyres have been used for many years but on many farms after 30 to 40 years they are past well past

their sell by date, are losing wires and need to be replaced urgently.

Two of the least popular jobs on the farm are tyring a pit with dirty, wet, stinking, old tyres and forking waste off the top of a badly sealed pit.

To make top quality silage with minimal waste and maximum feed value, roll silages well, avoiding any slopes greater than 30o, seal the clamp immediately ensuring that it really is air tight and protect the sheets with protective woven silage covers.

Covering the entire silage pit surface with Lorry Tyre Sidewalls consolidates the top layers of silage, tightens the silage sheets, prevents air pockets and and keeps the pit covers in tight contact with the silage surface reducing waste. Small amounts of waste on the top of a silage pit and unseen losses in the top metre can represent thousands of pounds worth of silage. Waste which was easily preventable.

Lorry Tyre Sidewalls are the perfect replacement for

old car types on silage clamps. Lorry Tyre Sidewalls cover a lot of silage very quickly. It takes half

the time and labour to cover a pit compared with using old car tyres.

Lorry Tyre Sidewalls are the perfect replacement for

old car types on silage clamps. Lorry Tyre Sidewalls cover a lot of silage very quickly. It takes half

the time and labour to cover a pit compared with using old car tyres.

They apply an even weight across the whole silage clamp surface and are much cheaper and easier to handle than heavy rubber silage mats.

Unlike rubber mats they do not blow off the pit in exposed, windy situations and unlike like gravel bags they cover the whole surface, last many times longer and are much cheaper.

Seal silage clamps with

oxygen barrier film

Woven protective silage covers prevent damage

to sheets

Lorry tyre sidewalls add weight evenly to the surface of the pit

Lorry

Tyre Sidewalls are clean, dry, all the same size, easy to handle, easily stacked, cheap and effective.

Handling can easily be mechanised. They and can be

stacked on pallets or handled with pallet forks or bale spikes. Lorry tyre sidewalls cost a fraction

of the price of rubber silage cover mats and are much easier to handle.

Lorry

Tyre Sidewalls are clean, dry, all the same size, easy to handle, easily stacked, cheap and effective.

Handling can easily be mechanised. They and can be

stacked on pallets or handled with pallet forks or bale spikes. Lorry tyre sidewalls cost a fraction

of the price of rubber silage cover mats and are much easier to handle.

Leaned against a wall they can be stored clean and dry ready to use and take up very little space. Stored in this way they can easily be moved to a new position or taken straight onto the silage pit 50 at a time using pallet forks.

Lorry Tyre Sidewalls are definitely the cheapest, most effective solution for covering and weighting silage sheets, covers and nets in order to reduce waste and loss of feed value on the top of silage pits.

Silage is too valuable a resource to accept any avoidable waste or loss of feed value resulting from inadequate rolling, sheeting or sealing of the silage clamp. Always use an effective silage additive, a proven oxygen barrier film, a protective silage cover and use lorry tyre sidewalls to apply weight over the entire surface of the pit.

Use Lorry Tyre Sidewalls on grass and maize silage, wholecrop and straw stacks.

RWN Tyre Sidewalls make a fantastic silage covering system

Lorry or Truck Tyre Sidewalls have many Advantages :

- They cover 1 square metre each - Much quicker than tyres

- Easy to handle - 12kg-13kg carried in each hand

- Clean and Dry - Easy to use and contain no water

- Tidy and Stackable - Can easily be stacked or stored vertically against a wall

- Handling can easily be mechanised - Move on 50 at a time on pallet forks

- Easy to store - No heaps of wet, dirty tyres full of nettles. Very quick to apply

- Lorry Tyre Sidewalls are Extremely Durable - Expected life 50 years

- Inexpensive (cost 1-3p/t of silage) - Written off over 15 years cost is negligible

- Labour Saving - Can reduce Labour Costs by 1-3p/t of silage compared to car tyres

- Reduced top waste on silage - Saves work, more feedable silage, less mycotoxins, reduced purchased concentrate costs

- SAVES MONEY - More milk from less forage and healthier cows

Much Better than Car Tyres. Much Cheaper than Rubber Silage Mats

Much More Effective than Silage Nets alone

Cost per Tonne of Silage is Negligible

Tyre Sidewalls are the Best Covering for Silage Clamps

Quality

forages are too valuable a resource to waste. A three metre deep silage clamp containing 1800 tonnes

of forage worth £50,000 can be covered by one load of tyre sidewalls, which written off over 15

years would cost less than £50 per year.

Quality

forages are too valuable a resource to waste. A three metre deep silage clamp containing 1800 tonnes

of forage worth £50,000 can be covered by one load of tyre sidewalls, which written off over 15

years would cost less than £50 per year.

RWN Lorry Tyre Sidewalls or Tyre Rings are an effective solution to top waste on a wide range of forages and moist feeds including grass silage, wholecrop cereals, crimped cereals, forage maize and moist feeds.

Click to see more Lorry Tyre Sidewalls on Silage Clamps , on Protective Silage Covers and Lorry Tyre Sidewalls in bundles as they are delivered and Lorry Tyre Sidewalls stacked ready for use.

Still got questions and want to know more? Check out our Tyre Walls Frequently Asked Questions page.

BETTER SILAGE, REDUCED FEED COSTS, MORE MILK AND LESS HASSLE

Customer testimonials:

Cornwall, 2013 "Best thing we've ever used. The staff are all laughing and joking when they are sheeting up. Unheard of when we used tyres. And you cover such a lot of ground so quickly. Used with Oxygen Barrier Film and Protective Silage Covers, no waste on the top at all"

A Cheaper and More Effective Clamp Sealing System

For advice on making better silage, reducing waste and cutting feed costs check our Silage FAQ page or for prices and availability of Oxygen Barrier Film, Gravel Bags, Protective Silage Nets and Lorry Tyre Sidewalls contact Richard Webster.

We can supply full loads throughout England, Wales, Scotland. Availability of Tyre Sidewalls can be very limited during the silage season unless ordered ahead of time. We recommend ordering several months in advance of requirement.