Silage Additives Frequently Asked Questions

Silage additives have been widely used in the UK for well over 50 years yet there is still a widespread

lack of understanding amongst farmers, contractors, advisors and suppliers, of their mode of action,

how they work, their limitations, benefits of use and which products are most appropriate for a particular

situation. This is hardly surprising since silage making is an extremely complex process with many variables

and with many opportunities for things to go wrong.

Silage additives have been widely used in the UK for well over 50 years yet there is still a widespread

lack of understanding amongst farmers, contractors, advisors and suppliers, of their mode of action,

how they work, their limitations, benefits of use and which products are most appropriate for a particular

situation. This is hardly surprising since silage making is an extremely complex process with many variables

and with many opportunities for things to go wrong.

The Importance of Quality Silage: Our aim at RWN is to work towards improving the quality of UK silages with a view to increasing animal output and milk yields without the need to spend a fortune on additional concentrates.

Better silages produce more milk, are better for cow health, reduce input costs, and result in more profit for the farmer. Better grass, maize or wholecrop silages do not cost significantly more to make than poor silages, but they do require more attention to detail.

Selecting the most effective silage additive for the job is one of many important factors which affect the quality of the silage made

The Ultra-Sile

Range of Biological Silage Additives is in our view the most technically advanced, most

versatile and comprehensive range of forage additives available to farmers in the UK. The range includes

products offering extremely reliable results over a wide range of conditions.

The Ultra-Sile

Range of Biological Silage Additives is in our view the most technically advanced, most

versatile and comprehensive range of forage additives available to farmers in the UK. The range includes

products offering extremely reliable results over a wide range of conditions.

Attention to detail and the use of a quality silage additive appropriate to the situation will go a long way towards producing very high quality and valuable feed with greatly reduced losses most of the time.

Our aim at RWN is to increase the quality of UK silages with a view

to increase

milk yields without the need to spend a fortune on additional concentrates

This FAQ's page attempts to offer at least some clarity to both making consistently better silages and selecting the most appropriate silage additive for your situation.

Better silages produce more milk, are better for cows and produce more profit

Frequently Asked Questions

Inoculants and Silage Making

What are the benefits of using a silage additive?

What are the benefits of using a silage additive?- How do silage additives work?

- How can I justify the cost of a silage additive?

- Silage additives are just insurance against bad weather?

- Why use a silage additive when the sun is shining?

- Do I need a silage additive on grass silage above 30% DM?

- By not using a silage additive I am saving money?

- How much money will I save by using a silage additive?

- Why should I use a silage additive on forage maize?

Is there any point using an additive on youngstock silages?

Is there any point using an additive on youngstock silages?- Should I use a silage additive on big bale silage?

- My silage heats on the face. Is it the fault of the additive?

- My current additive has more trial work than other additives?

- My silage keeps running effluent. Is this due to the additive?

- Acid was always the best silage additive?

- Will a preservative do a better job than an inoculant?

- Aren't all biological silage additives pretty much the same?

- The silage additive I use is brewed on the farm to save money?

How can I reduce spoilage and dry matter losses?

How can I reduce spoilage and dry matter losses?- How can I improve the ME and crude protein of my silages?

- Why hasn't the silage additive worked?

- My silages are low in energy. Would a different additive help?

- Are there better silage additives out there?

- Will an inoculant work in very wet and dirty conditions?

- What is the best silage additive to prevent silage going butyric?

- My high lactic acid, low pH silage is causing acidosis?

- Why use anything other than Lactobacillus plantarum?

Are multi-strain inoculants better than single strain products?

Are multi-strain inoculants better than single strain products?- How important are the number of bacteria applied?

Ultra-Sile Silage Additives

- Are Ultra-Sile silage additives new?

- Why haven't I heard about Ultra-Sile silage additives before?

- How was the Ultra-Sile Range developed?

- My current supplier says that Ultra-Sile has not been tested?

- Do Ultra-Sile Additives have any trial work?

- Are Ultra-Sile silage additives fully approved and registered?

Why are Ultra-Sile silage additives better?

Why are Ultra-Sile silage additives better?- Why are there so many products in the Ultra-Sile Range?

- Can I use one silage additive to treat all my crops?

- How many bacteria do Ultra-Sile inoculants apply?

- Do Ultra-Sile additives apply 1 million Lactobacillus plantarum?

- Will Ultra-Sile improve face stability and prevent heating?

- Will Ultra-Sile silage additives prevent top and shoulder waste?

- Will Ultra-Sile silage additives cope with wet, low sugar grass?

- Do I need to mix Ultra-Sile silage additives the day before?

- What is the application rate for Ultra-Sile silage additive?

How long will Ultra-Sile silage additives last once mixed?

How long will Ultra-Sile silage additives last once mixed?- My contractor prefers Ultra Low Volume ULV additives?

- Do Ultra-Sile additives come in ULV and Granular options?

- Will Ultra-Sile silage additives help us reach net zero carbon emissions?

- Are Ultra-Sile silage additives suitable for organic use?

- How quickly can Ultra-Sile silage additives be delivered?

- Should I take advantage of early order?

- How do I place an order?

INOCULANTS AND SILAGE MAKING

1. What are the benefits of using silage additive?

The benefits of using an inoculant based silage additive across a wide range of fermented forages is well documented and supported by hundreds of trials both in the UK and overseas.

Using an inoculant speeds up and improves the efficiency of the fermentation process. The result is a more palatable silage with improved stability and which has a feed value closer to that of the crop at harvest, which has lost less feed value and dry matter in the process and is capable of supporting higher levels of animal performance.

Typically inoculants will reduce dry matter losses in storage by up to 4.5% in grass silage equivalent to an additional 45 tonnes of silage at feed out for every 1000 tonnes treated.

Digestibility and

energy levels are generally higher, protein degradation is cut by about half, and intake characteristics

are improved.

Digestibility and

energy levels are generally higher, protein degradation is cut by about half, and intake characteristics

are improved.

The improvements to silage as a result of using a silage additive have never been easy to measure by silage analysis especially with regard to intake potential and animal performance. But with experience smell and taste reveal that the differences are easily apparent. Cows can certainly tell the difference.

One of the main benefits of treating silage with additive is financial

From the farmers point of view one of the main benefits of using a silage additive is financial. There is more better quality silage to feed as a result of using a silage additive, animals perform better and purchased concentrate costs can be reduced.

Typically yield responses over large numbers of research trials have averaged up to 1.5 litres of milk per cow per day. Live weight gain on heifers and beef stock have been shown to increase by as much as 30% when fed additive treated grass silage.

On average you might expect a 10 : 1 return on the cost of treatment

It is difficult to understand why the use of silage additives in the UK is still not universal. Back to top

2. How do silage additives work?

"Silage

is the product formed when grass or any other material of sufficiently high moisture content (and thereby

liable to spoilage by microbes which thrive in air) is stored in the absence of air" .

This definition was coined by Whittenbury (1968). Normally bacteria ferment sugars, producing lactic

and acetic acids and other non-acid products. This results in an increase in acidity and drop in pH which

prevents the growth of clostridia, which would otherwise thrive and produce butyric acid and other

noxious substances, and which also prevents the growth of yeasts and fungi.

"Silage

is the product formed when grass or any other material of sufficiently high moisture content (and thereby

liable to spoilage by microbes which thrive in air) is stored in the absence of air" .

This definition was coined by Whittenbury (1968). Normally bacteria ferment sugars, producing lactic

and acetic acids and other non-acid products. This results in an increase in acidity and drop in pH which

prevents the growth of clostridia, which would otherwise thrive and produce butyric acid and other

noxious substances, and which also prevents the growth of yeasts and fungi.

The concept of inoculating silages with elite strains of bacteria in order to control and carry out an efficient, rapid, cool fermentation with minimum loss of energy, protein and other nutrients, as opposed to natural fermentation conducted by whatever microbes happened to be present on the day, is now widely accepted throughout the World.Back to top

3. How can I justify the cost of a silage additive?

Silage additives were a good economic proposition in the early 1980's. Since then the economics of using additives on silage have improved markedly. Over the past 40 years milk prices as well as the cost of forage and concentrates have more than doubled whilst silage additives have improved in quality and reduced in price by around 30%. There is now no economic justification for not using an additive on any fermented forage crop at today's prices.

A

review of 256 additive trials (Jones R, IGER 2005) showed that bacterial inoculant

treated silages had higher DM digestibility and reduced levels of protein degradation. The average response

in milk production trials was over 1.5 litres of milk /cow/day.

A

review of 256 additive trials (Jones R, IGER 2005) showed that bacterial inoculant

treated silages had higher DM digestibility and reduced levels of protein degradation. The average response

in milk production trials was over 1.5 litres of milk /cow/day.

With milk prices at around 45 pence per litre this would represent over £0.65 /cow/day at today's prices whilst the cost of treating the silage is equivalent to 3 - 5 pence /cow/day. Trials have also shown benefits in terms of milk quality, body condition, fertility etc.

On average trial results have shown a reduction in fermentation and storage losses on treated grass silage of up to 4.5%. A saving of 45 tonnes of silage worth say £45 / tonne on every 1000 tonnes treated is worth £1800 compared with a treatment cost of £900 - £1250.

Silage additives can also reduce heating at the face and aerobic losses during feed out. It has been estimated that for every 1oC rise in clamp temperature above ambient, 0.23% DM is lost each day.

Research has demonstrated typically 10 : 1 return on the cost of treatment

Combining savings in dry matter with animal performance benefits results in a typical return on investment of 10 : 1 and could represent an increase in margin per cow of £100 over a winter. Back to top

4. Silage Additives are just insurance against bad weather?

It is true that in the early days of silage making acids were used as an 'insurance' in bad weather to prevent wet grass silages from turning butyric. Today biological inoculants have replaced chemical acid additives almost exclusively and for good reason. Inoculation takes control of the fermentation using highly efficient elite strains of bacteria to carry out the fermentation rather than allowing an inefficient and unreliable fermentation to result from whatever microbes happened to be present on the crop on the day and which would have included a host of spoilage organisms.

The use of modern additives has little to do with the weather

Hundreds

of trials have proven that animal performance is improved when silage is treated with an inoculant based

silage additive, whether or not the weather is good or bad. This is due to more efficient use of sugars

to produce acids. Sugars are used around twice as efficiently with a silage additive. About half as much

protein is degraded. Much less heat is produced over a much shorter time. So much less energy wasted.

Fewer spoilage organisms are present. Silage is more palatable and has improved intake characteristics.

Hundreds

of trials have proven that animal performance is improved when silage is treated with an inoculant based

silage additive, whether or not the weather is good or bad. This is due to more efficient use of sugars

to produce acids. Sugars are used around twice as efficiently with a silage additive. About half as much

protein is degraded. Much less heat is produced over a much shorter time. So much less energy wasted.

Fewer spoilage organisms are present. Silage is more palatable and has improved intake characteristics.

All fermented forages should be treated with silage additive even in good weather

These benefits are nothing to do with bad weather. They are about taking control of the fermentation and preventing less effective micro-organisms, spoilage organisms, moulds and yeasts from wasting valuable nutrients and spoiling the clamp. Back to top

5. Why use a silage additive when the sun is shining?

The myth that "sunshine is the best silage additive" stems from the early days of using acid additives to prevent wet high nitrogen grass silages from going butyric. This misunderstanding of how biological inoculant based additives work has cost the industry many millions of pounds over the years.

Inoculants give a rapid and efficient fermentation completing in days rather than in weeks when not treated. The clamp remains relatively cool with energy and dry matter losses much lower than with un-treated silage. Much less protein is degraded and more of the protein is in a form that cattle can use for production. These benefits apply irrespective of ensiling conditions or grass dry matter.

The benefits of treating all forages with silage additive in all conditions

even when the sun is shining are well proven

The

benefits of treating all silages even in good, sunny conditions have been illustrated by 11 dairy trials

at Hillsborough where treated grass silages cut in good conditions increased milk yields by 1.3 litres

per cow compared with untreated control silages.

The

benefits of treating all silages even in good, sunny conditions have been illustrated by 11 dairy trials

at Hillsborough where treated grass silages cut in good conditions increased milk yields by 1.3 litres

per cow compared with untreated control silages.

Similarly a trial at IGER in good conditions increased live weight gain on beef animals from 0.8 to 1.1 kgs per day compared with untreated silage an increase of 37%.

In practice it is cheaper to treat forages when conditions are good, since the application rates of most silage additives are per tonne of fresh weight forage. This means that only half the silage additive would be needed per acre to treat silage at 36% DM compared with silage at 18% DM. Contrary to popular belief treating silage with an additive in good dry conditions may give an even better return than treating silage in wet conditions.

Silage additive treatment in dry conditions may give an even better return

than when used in wet conditions

The logic for applying silage additive at a lower rate in dry conditions is that there are generally more sugars, and less acid is needed to preserve the silage since there is less water present and often there is less soil contamination. There is less risk of going butyric, the fermentation is easier and fewer inoculant bacteria are needed in order to dominate the fermentation. Back to top

6. Do I need a silage additive on dry silages above 30% dry matter?

Untreated,

drier grass silages will not go butyric but will still take up to 6 weeks to ferment. They tend to heat

to higher temperatures for longer, lose more energy, lose dry matter, have typically double the protein

broken down and be less palatable than additive treated silage.

Untreated,

drier grass silages will not go butyric but will still take up to 6 weeks to ferment. They tend to heat

to higher temperatures for longer, lose more energy, lose dry matter, have typically double the protein

broken down and be less palatable than additive treated silage.

Untreated silages are also likely to produce reduced levels of animal performance and to have an increased risk of mycotoxin contamination and aerobic instability with heating at the face. All dependent of course on the type of silage additive used.

We would not recommend the use of a lactic only product on silage above 30% DM which may actually increase the risk of heating due to the reduced levels of volatile fatty acids produced by a homo-lactic fermentation. Use an inoculant, based on hetero-fermentative strains of bacteria, which are capable of producing more volatile fatty acids including acetic acid and propionic acid, in order to reduce the risk of heating at the silage face.

Typically silage additives can yield a return on investment

of 10 : 1 even in good weather

A great deal of trial work has been carried out looking at the silage additive treatment of drier silages and it is quite clear that use of an inoculant will generally give a much more efficient fermentation, with reduced dry matter losses and improved animal performance.

Less silage additive is used on dry silages since recommended application rates are per tonne of fresh weight forage and dry silage weighs less. Therefore silage additives cost less per tonne of dry matter when silage is drier but benefits are likely to be similar to treating wet silages.

Typically silage additives will yield a return on investment of 10 : 1 even on dry silages. Back to top

7. By not using a silage additive I am saving money?

Silage

additives have a cost, equivalent to 3 - 5 pence per cow per day. A large number of trials with dairy

cows have shown an average milk yield response, irrespective of weather conditions of up to 1.5 litres

per cow per day. So for less than 5 pence you are likely to get back 45 - 65 pence, on every cow, every day.

Not a bad investment.

Silage

additives have a cost, equivalent to 3 - 5 pence per cow per day. A large number of trials with dairy

cows have shown an average milk yield response, irrespective of weather conditions of up to 1.5 litres

per cow per day. So for less than 5 pence you are likely to get back 45 - 65 pence, on every cow, every day.

Not a bad investment.

You will of course also have more silage to feed and silage of better quality. On average with grass silage, additive treatment has been shown to cut fermentation and storage dry matter losses by about 45 tonnes for every 1000 tonnes treated.

Not using a silage additive definitely costs you money!

Silages have also been shown to have more true protein, more energy and higher digestibility when treated with a good quality inoculant resulting in improved animal performance. So not using a silage additive is not saving money, it is costing money. There will be less silage to feed out and animals are likely to produce less and require more concentrates.

8. How much money will I save by using a silage additive?

If savings in silage DM losses cover the cost of the silage additive and cows give an extra 1.5 litres per day @ 45 ppl then on 100 cows you could potentially make an extra £65 worth of milk per day or £13,000 over a 200 day winter. Alternatively you could save some concentrates or keep fewer cows saving money. Personally I would go for the extra milk. Back to top

9. Why should I use a maize additive?

Maize

crops generally come in clean without high levels of soil contamination, clostridia, nitrogen and always

have plenty of fermentable sugars. Consequently maize silage never goes butyric and is usually between

25% and 40% DM and is therefore a relatively easy crop to ferment. Many farmers who always use an additive

on grass silage, don't bother to use a maize additive.

Maize

crops generally come in clean without high levels of soil contamination, clostridia, nitrogen and always

have plenty of fermentable sugars. Consequently maize silage never goes butyric and is usually between

25% and 40% DM and is therefore a relatively easy crop to ferment. Many farmers who always use an additive

on grass silage, don't bother to use a maize additive.

Often their main criteria for using a maize additive has been to improve face stability. Some have used a homo-fermentative inoculant which will give a very rapid fermentation but which produces only lactic acid. Lactic acid is rapidly broken down by lactate assimilating yeast in situation where silage begins to heat on the face. They have then concluded, mistakenly, that there is no point using a maize additive on forage maize silage.

My view is that it is indeed, very cost effective to treat forage maize with an appropriate hetero-fermentative inoculant. Additive treatment of maize will generally reduce dry matter losses in the clamp, improve feed intakes, improve face stability, reduce face heating, reduce mycotoxin levels and improve animal performance. Maize silage ferments in the same way as grass silage and for best results all forage maize should be treated with an effective maize additive such as Ultra-Sile Maize.

Typically, since maize silage is drier and undertakes a less extensive fermentation than wet

grass silages, I might expect around 4% reduction in fermentation and storage losses

compared with 4.5% - 5% in grass silage, as a result of using a silage additive.

Typically, since maize silage is drier and undertakes a less extensive fermentation than wet

grass silages, I might expect around 4% reduction in fermentation and storage losses

compared with 4.5% - 5% in grass silage, as a result of using a silage additive.

If we assume that silage additive treatment will cost between £0.85 and £1.20 per tonne treated and maize silage is worth £45 per tonne a 4% saving equates to an additional 40 tonnes of maize silage worth £1800 to feed for every 1000 tonnes treated. So even before taking account of improved feed value, fewer mycotoxins and improved animal performance it is definitely cost effective to treat all forage maize crops with a maize additive.

10. Is there any point using a silage additive on youngstock silages?

In the AIC Forage Additives Register 2005, 34 biological silage additives were registered as having demonstrated that they improved live weight gain. Each of these would have had at least 3 independent trials in order to have gained approval. A review of beef cattle trials confirm the economic benefits of inoculation of grass silages resulted in improvements in liveweight gain of 24% and increases in dry matter intake of 7% compared with animals fed untreated grass silage.

Typical increases in live weight gain on grass silage diets might be expected to

be around 0.1 to 0.15 kg per day along with improvements in feed conversion efficiency of up to 23%.

You might expect a dairy heifer to calve down 50kg heavier or 1 - 3 months earlier.

Typical increases in live weight gain on grass silage diets might be expected to

be around 0.1 to 0.15 kg per day along with improvements in feed conversion efficiency of up to 23%.

You might expect a dairy heifer to calve down 50kg heavier or 1 - 3 months earlier.

As well as increased growth rates there is scope for a reduction in concentrate use in order to reduce costs on heifers and growing beef animals.

On average silage additive treatment of grass silages has been demonstrated to reduce fermentation and storage losses in the clamp by around 4.5% equivalent to 45 tonnes of additional silage for every 1000 tonnes treated. This applies irrespective of weather conditions or the maturity level of the silage.

With silage additives costing between £0.90 and £1.30 per tonne treated if grass silage is valued at £30 per tonne savings in dry matter losses more than cover the cost of the silage additive before taking account of reduced losses due to heating at the face, or of increased growth rates or reduced concentrate costs.

There is absolutely no question that the failure to use a silage additive on silages for heifers, youngstock and beef cattle actually costs the farmer money. Back to top

11. Should I use a silage additive on big bale silage?

Yes.

Big bales ferment in exactly the same way as clamp silage. Treating big bale grass silage or Ag-Bagged

fermented forage crops whether grass, whole crop cereal or maize, with an inoculant, will yield the same

benefits as would a clamp. All fermented crops deserve to be treated with a silage additive.

Yes.

Big bales ferment in exactly the same way as clamp silage. Treating big bale grass silage or Ag-Bagged

fermented forage crops whether grass, whole crop cereal or maize, with an inoculant, will yield the same

benefits as would a clamp. All fermented crops deserve to be treated with a silage additive.

Trials have shown that additive treated bales often weigh 10% heavier after storage than untreated bales. Cows offered treated or untreated bales usually eat the treated bales first.

Many trials have demonstrated that youngstock, beef, heifers and lambs all improved growth rates on additive treated silage resulting in either reduced maintenance costs or reduced concentrate costs. Treatment costs of £0.50 to £0.90 per bale are easily justified even before taking account of improved animal performance. Silage additive applicators for big bales can be obtained from Selmech. Back to top

12. My silage heats on the face. Is it the fault of the silage additive?

Heating

or aerobic spoilage at or just behind the silage face is due to a number of factors including consolidation,

clamp sealing, silage dry matter, chop length, maturity, sugar levels, nitrogen, protein levels

and buffering capacity which will in turn affect the extent of the fermentation and the amount of acid

present.

Heating

or aerobic spoilage at or just behind the silage face is due to a number of factors including consolidation,

clamp sealing, silage dry matter, chop length, maturity, sugar levels, nitrogen, protein levels

and buffering capacity which will in turn affect the extent of the fermentation and the amount of acid

present.

Crop contamination with yeasts and moulds will also have a bearing as will ambient temperature levels and rate of feed out.

Below 25% DM, well consolidated silage clamps rarely heat provided that usage rates are at least 15cms per day, face management is good and ambient temperatures are not above 10oC to 15oC irrespective of what silage additive is used. The problem is that above 30% DM, air can easily penetrate 1- 2 metres into the clamp which gives plenty of time for spoilage organisms to get to work. Once the silage starts to warm, spoilage speeds up and lactate assimilating yeasts can rapidly break down lactic acid.

For this reason with dry silages it is unwise to use homo-lactic silage additives which produce

only lactic acid. Instead use biological additives based on hetero-fermentative strains of bacteria designed

for use on higher dry matter silages such as Ultra-Sile Dry or Ultra-Sile HiDri.

For this reason with dry silages it is unwise to use homo-lactic silage additives which produce

only lactic acid. Instead use biological additives based on hetero-fermentative strains of bacteria designed

for use on higher dry matter silages such as Ultra-Sile Dry or Ultra-Sile HiDri.

Often heating starts in the top third of the pit. This is due to poorer consolidation near the top, drier silages near the top and air present during the first days of the fermentation which allows spoilage organisms to multiply rapidly.

Silage Additives are no replacement for good management practices

Heating

on the face can be influenced by choice of silage additive. The faster the initial part of the fermentation

down to pH 5, the less opportunity there is for spoilage organisms to multiply. Multi-strain inoculants

designed for a rapid start will help. Also using high specification silage additives with hetero-fermentative

strains which are capable of producing acetic, propionic and other acids will also help to reduce the risk of heating.

Heating

on the face can be influenced by choice of silage additive. The faster the initial part of the fermentation

down to pH 5, the less opportunity there is for spoilage organisms to multiply. Multi-strain inoculants

designed for a rapid start will help. Also using high specification silage additives with hetero-fermentative

strains which are capable of producing acetic, propionic and other acids will also help to reduce the risk of heating.

No silage additive can work effectively where the silage has not been rolled or where the clamp is not fully sealed

No silage additive can work effectively where the silage has not been rolled or where the clamp is not fully sealed. Shrinkage or DM loss can be cut by about 40 tonnes in a 1000 tonne clamp simply by increasing the density of the silage by a third. For best results aim for 25% - 28% DM, chop short, roll well, use direct cut grass on the top 1 - 2 metres, side sheet and sheet up as soon as the pit is full. Using a low transmission Passion Ag Oxygen Barrier Film has been shown to delay heating on the face by up to 5 days. But make sure that all edges and seams are completely air tight before applying nets, and tyres or lorry tyre side walls for additional weight. Having done that, wait at least 6 weeks before opening the pit and ensure that usage rates are at least 15cms /day in cold weather and at least 30 cms / day in summer. Back to top

13. My current silage additive has more trial work than other additives?

More

trial work doesn't necessarily mean a better product. Most silage additives put through independent research

trials use no silage additive as the control treatment. The aim being to gain a positive improvement

against using no additive for the purposes of obtaining registration with an approval scheme.

More

trial work doesn't necessarily mean a better product. Most silage additives put through independent research

trials use no silage additive as the control treatment. The aim being to gain a positive improvement

against using no additive for the purposes of obtaining registration with an approval scheme.

In many cases the companies that have invested the most in independent trials have been the most reluctant to update their products to incorporate the latest research, greater understanding of the silage making process and changes to forage conservation techniques.

Smaller specialised companies with a heavy on farm presence on the other hand have often been much more innovative and more able to respond to the changing needs of farmers. Back to top

14. My silage keeps running effluent. Is this due to the Additive?

Most biological inoculants actually reduce effluent losses, whilst acids can rupture the cell wall and increase effluent losses. When the UKASTA / AIC Forage Additives Register was still in operation in 2005 over half the inoculants registered, but none of the acids and salts, had gained approval for reduced effluent flow. Effluent contains valuable nutrients and should therefore be minimised. A rapid wilt to 26% - 30% DM should be the aim. Tedding immediately after mowing can result in a dramatic five fold increase in wilting rates.

Effluent flow is normally minimal above 25% dry matter but can be prolific below 20% DM. Not surprising when we consider that at 15% DM the clamp is 85% water, or not much thicker than milk. All silage clamps do produce some water. This is due to dry matter losses. The best fermentations have a fermentation loss of around 6% - 8%. A badly fermented grass silage may have fermentation and storage losses of over 30% which may reduce DM% by 2% - 3%. As organic matter is used as an energy source during the fermentation heat, carbon dioxide, acids and water are generated.

Using an inoculant increases the speed and efficiency of the fermentation, reduces energy lost as heat and reduces dry matter losses and therefore the amount

of water produced. Effluent flow is therefore reduced, in some cases showing more than a 20% reduction.

In contrast acids can increase effluent flow by over 40%.

Using an inoculant increases the speed and efficiency of the fermentation, reduces energy lost as heat and reduces dry matter losses and therefore the amount

of water produced. Effluent flow is therefore reduced, in some cases showing more than a 20% reduction.

In contrast acids can increase effluent flow by over 40%.

Wet grass silages need more acid to preserve them than dry grass silages and undergo a more extensive fermentation with higher fermentation losses and therefore slightly more water produced.

Air present at the start of the fermentation will delay fermentation and increase losses. As a general rule if the fermentation is good and the silage is stable losses will be low and the silage additive has done a good job. The better the fermentation at a given dry matter, the lower the losses.

Where the silage is badly fermented, butyric or unstable then dry matter losses will be higher and consequently the dry matter % of the silage will fall. This may be due to the silage additive failing to control the fermentation. This can be due to many reasons, for example, application issues, or a forage so high in clostridia, soil, nitrogen, or too low in DM or sugars to be capable of preservation under any circumstances. That said some additives cope much better than other in challenging situations.

Most

times that clamps appear to get wetter and run more effluent it is due to rain water penetrating the

silage sheets on outside clamps. It is not uncommon to hold up a black sheet to sunlight to see it pin

holed all over due to bird damage or the claws of cats, dogs, foxes etc. In addition water often enters

at seams and shoulders.

Most

times that clamps appear to get wetter and run more effluent it is due to rain water penetrating the

silage sheets on outside clamps. It is not uncommon to hold up a black sheet to sunlight to see it pin

holed all over due to bird damage or the claws of cats, dogs, foxes etc. In addition water often enters

at seams and shoulders.

One metre of rain on 2 metres of 30% DM silage could reduce the clamp to around 17% DM if it all entered evenly across the surface. In practice water often pools in low places and I have seen cases of 4 metre deep clamps of 28% DM silage reduced to 17% DM over 2 - 3 bays with a subsequent loss in milk yield of several litres per cow.

This is why constructing clamps with a slight dome, doing a thorough job of sheeting and then protecting the sheets with protective covers or nets is so important. The sides should be dished inwards slightly to channel water away from the walls and off the front of the pit. Generally using two plastic sheets is better than one. Ideally use Passion Ag or Silostop Oxygen Barrier Film, a black sheet and then a protective net.Back to top

15. Acid was always the best silage additive?

Acids

have lost popularity in the UK due to health and safety issues, corrosion of silos, concrete and machinery,

and also the high cost. Applying 5 litres of acid per tonne is far more costly than treating with an

inoculant additive. Contrary to popular belief applying 5 litres of acid per tonne of silage reduces the pH by very little. The clamp

still has to undergo a normal fermentation to reach a stable pH and may produce an additional

30 - 40 litres of lactic acid in order to stabilise the clamp.

Acids

have lost popularity in the UK due to health and safety issues, corrosion of silos, concrete and machinery,

and also the high cost. Applying 5 litres of acid per tonne is far more costly than treating with an

inoculant additive. Contrary to popular belief applying 5 litres of acid per tonne of silage reduces the pH by very little. The clamp

still has to undergo a normal fermentation to reach a stable pH and may produce an additional

30 - 40 litres of lactic acid in order to stabilise the clamp.

Acids do give an initial pH drop which may reduce some multiplication of clostridia, yeasts and spoilage organisms. They do however dramatically increase effluent losses in wet grass silages and improvements in intakes or animal performance have rarely been demonstrated. Increased effluent losses reduce sugar levels in the silage and rupturing the plant cell walls may aid consolidation. As a result stability may be improved but at a cost.

Another issue particularly with very dry crops is that an inoculant will grow and continue to ferment until the silage is stable, whereas acid will stay where it is put. Uneven or insufficient application of acid can cause major problems. Generally inoculants are far more user friendly, much cheaper and result in lower losses, better intakes and improved animal performance compared with an acid. Back to top

16. Will a preservative do a better job than an inoculant?

Food preservatives such as potassium sorbate, sodium benzoate and sodium nitrite do have a place. They are much safer to use than strong mineral acids but they are more expensive to use than inoculants particularly on low dry matter forages where the amount needed to stabilise a clamp would be prohibitive.

Once

the pH of the clamp has fallen to a low level preservative are very effective at controlling moulds,

yeasts and spoilage organisms.

Once

the pH of the clamp has fallen to a low level preservative are very effective at controlling moulds,

yeasts and spoilage organisms.

However preservatives have little effect at the start of the fermentation until the pH drops to below 5, unless they are applied at very high concentration. Spoilage organisms, yeasts and moulds multiply very rapidly above 5 pH and can multiply to very high levels where a preservative is applied without an inoculant and the pH is slow to drop.

Applying preservatives without an inoculant will not have the same advantages of an inoculant in controlling the fermentation, in conserving energy, in reducing protein degradation and in improving intake characteristics. Where we have seen this approach commercially even with very high levels of preservative which has been very costly, whilst face stability has been comparable to the best hetero-fermentative inoculants, dry matter intakes and animal performance have been reduced.

Dual action preservative inoculant combinations are more effective

than preservatives used alone

Preservatives

used in a dual action combination with an effective inoculant can be very beneficial at only a small

additional cost over using an inoculant alone.

Preservatives

used in a dual action combination with an effective inoculant can be very beneficial at only a small

additional cost over using an inoculant alone.

The inoculant gives all the benefits of a rapid pH drop and an efficient fermentation aided by the preservative which will inhibit spoilage organisms as the pH drops resulting in good face stability in conjunction with a homo-lactic fermentation.

Dual action preservative inoculant combinations can be particularly effective where there is a high level of mould and yeast contamination on the crop in the field. Back to top

17. Aren't all biological silage additives pretty much the same?

Since the introduction of the UKASTA / AIC Forage Assurance Scheme which has now been followed the EU EFSA Approval Scheme we can be assured that all silage additives available in the UK are safe to use, meet quality standards and have demonstrated that they are effective and will show an improvement over un-treated silage. Registration however will not tell us which products are most effective or which are most appropriate for use in a given situation. Nor will a lot of the trial data often quoted by some silage additive companies as proof that their product is best.

Research trials comparing a particular silage additive against un-treated

silage, do not give much if any of an indication which is the best product out there for a given set

of circumstances. For that you will need to consult someone who has the on farm experience and know how

to be able to advise.

Research trials comparing a particular silage additive against un-treated

silage, do not give much if any of an indication which is the best product out there for a given set

of circumstances. For that you will need to consult someone who has the on farm experience and know how

to be able to advise.

Unfortunately often the people asked to give advice on choice of product do not have the necessary experience or knowledge of working with silage additives day in day out to give an informed opinion.

There are wide variations in the specifications of silage additives available in the UK and also in the results that they produce.

This is quite a dilemma for the farmer since due to the complex nature of silage fermentation and the microbiology and biochemistry few farmers have the expertise to judge the benefits of one silage additive against another. The problem is made worse since it is not uncommon for silage additives to be inadvertently sold into an inappropriate situation where another product could have done a much better job.

If you are making perfect silage right to the sheet, with no waste and no feeding issues, stick with the additive that you are using. If not find a silage specialist who can give really good advice, and remember, silage additives are no replacement for good management practices. It may not be the silage additive that is the problem.Back to top

18. The silage additive I use is brewed on farm to save money?

There have been a number of reduced rate silage additives available over the years which have been supplied at a small discount over full strength products and designed to be grown on farm.

Brew your own silage additives have largely fallen from favour for a number of reasons. One problem is that very acid tolerant strains of bacteria are needed which can tolerate very low pH and high acidity levels in the fermentation drum should silaging be delayed for a day or two.

As with a silage fermentation they will continue to ferment

in the drum until they are killed by the acidity and low pH. These products

are usually fast fermenting homo-lactic strains which are easy growers and have a shorter brewing time

than hetero-fermenters.

As with a silage fermentation they will continue to ferment

in the drum until they are killed by the acidity and low pH. These products

are usually fast fermenting homo-lactic strains which are easy growers and have a shorter brewing time

than hetero-fermenters.

Very acid tolerant strains of bacteria used in brew your own products are however, likely to ferment excessively in the clamp, using up more of the sugar, producing excessive amounts of lactic acid, which in term will increase the amounts of fermentation losses, and produce very low pH silages.

At the same time fully homo-lactic product do tend to produce silages which are prone to heating at the face in silages above about 25% DM. It is precisely for these reasons that many farmers have moved away from brew your owns to full spec freeze dried instant silage additives.

There have also been issues with heater elements failing and the silage additive not growing and issues with cross contamination where spoilage organisms have got into the brew. Also harvesting has to be anticipated ahead of time and if there is a delay then the brewed silage additive is either compromised or wasted completely.

In view of the fact that at current prices there can be a 10 : 1 return on the money spent on a normal full spec instant silage additive it is no wonder that brew your own products have fallen by the way side. Save 10% of the cost and risk losing 1000%. Back to top

19. How can I reduce spoilage and dry matter losses?

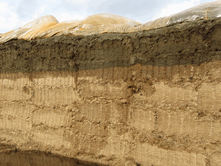

Dry matter losses during fermentation

and storage in silage pits range from about 7% to over 30%. All silages will lose some energy and dry

matter even in an efficient fermentation from respiration and as sugars are fermented to acids as part

of the acidification process.

Dry matter losses during fermentation

and storage in silage pits range from about 7% to over 30%. All silages will lose some energy and dry

matter even in an efficient fermentation from respiration and as sugars are fermented to acids as part

of the acidification process.

All effluent will contain dry matter which is another source of dry matter losses. In addition there may be further losses due to heating at the face and un-feedable spoiled silage which is discarded.

The challenge to silage makers is minimise those losses and finish up with a stable silage at feed out which has a feed value as close as possible to the crop when it was cut. The aim should be to have no visible spoilage or waste on the pit, and this is achievable.

In order to achieve low DM losses below 10% and no visible spoilage everything has to be done right with attention to detail and no corners cut. In short observe good silage management practice throughout.

Here are some of the

factors to consider. Grow a good clean crop in the field and use a mower conditioner. With grass silages

a rapid wilt to 25% - 28% dry matter (may only need 2 - 4 hours). Make sure you have a clean clamp, clean

yard, gateways and tracks.

Here are some of the

factors to consider. Grow a good clean crop in the field and use a mower conditioner. With grass silages

a rapid wilt to 25% - 28% dry matter (may only need 2 - 4 hours). Make sure you have a clean clamp, clean

yard, gateways and tracks.

Always use an effective silage additive, short chop, roll well with heavy machines and narrow tyres. Roll no more than 15cms at a time. Dish the sides so the rolling gets right to the wall. Save some wet forage for the top metre where possible.

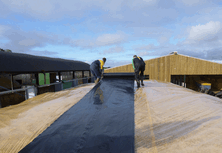

The clamp should be slightly domed to run off water but do not overfill the clamp. Have no shoulders or ramps greater than 30o slopes. Use Oxygen barrier film rather than cling film, side sheet with Oxygen barrier wall film, then a black sheet on top, then a net, and then apply weight evenly over the surface of the net. Tyres or lorry tyre sidewalls work well.

Use a quality inoculant designed for improved face stability

such as Ultra-Sile Dry or Ultra-Sile HiDri

Where crop dry matters are greater

than 28% DM or usage rates are low use a quality inoculant designed for improved face stability such

as Ultra-Sile Dry, Ultra-Sile HiDri, Ultra-Sile Maize or Ultra-Sile Arable.

Where crop dry matters are greater

than 28% DM or usage rates are low use a quality inoculant designed for improved face stability such

as Ultra-Sile Dry, Ultra-Sile HiDri, Ultra-Sile Maize or Ultra-Sile Arable.

Sheet immediately the pit is filled. All seams and edges must be airtight. Use gravel bags at edges and seams, bottom of the ramp and across the face. Tape the seams if necessary. Ideally do not open the clamp for at least 6 weeks.

At feed out use a block cutter or defacer and keep the clamp area clean. Ensure that usage rates are more than 15 cms in the winter and more than 30 cms in the summer. If this can't be achieved then redesign the clamping systems. Back to top

20. How can I improve the ME and protein of my silages?

If ME and protein levels of your silage are low then they can be improved. But remember a silage additive is not a replacement for good management practices. A silage additive will reduce losses in DM and energy and will keep more of the protein in an intact form that can be utilised directly by the animal but it will not turn a low digestibility, low protein forage into something better. Silage is never as good as the crop in the field. The best we can do is minimise losses and keep its feed value as close as possible to the fresh cut crop. Avoid long wilting periods. Rapid wilting reduces losses of both energy and protein.

The UK went through a period of cost cutting and corner cutting where some of the basic principles of grass silage making were largely forgotten. The move away from 3 and 4 cut systems, to 2 cut systems in an attempt to save money on contractors, has cost the industry a fortune in lost production, increased concentrate costs and animal health issues. Grass quality not yield is the key to making quality silage.

Cut 1st cut early and then cut every 5 - 6 weeks.

Always use a good silage additive

The

digestibility, ME and crude protein falls dramatically as a crop of grass reaches maturity. Once ear

emergence is reached a 7 day delay in cutting will result in a loss of 3-4 units of D-value and increase

the need for concentrates by around 1.5kgs per cow per day. Late headed varieties will reach optimum

cutting date up to 2 weeks before ear emergence. Lodged crops will lose about 1 unit a day in D-value.

So cutting early, really is of paramount importance and affects cow performance for the whole year.

The

digestibility, ME and crude protein falls dramatically as a crop of grass reaches maturity. Once ear

emergence is reached a 7 day delay in cutting will result in a loss of 3-4 units of D-value and increase

the need for concentrates by around 1.5kgs per cow per day. Late headed varieties will reach optimum

cutting date up to 2 weeks before ear emergence. Lodged crops will lose about 1 unit a day in D-value.

So cutting early, really is of paramount importance and affects cow performance for the whole year.

If you don't believe me try grazing a first cut grass silage in July. Yet there was a trend to delay cutting 1st cut until well into June and cutting 2nd cut in August or September. Aim for 1st cut early in May if conditions permit, and subsequent cuts 5 -6 weeks apart. Aim for 3 or 5 cuts per year.

Rotational grazing system work on around 3 week intervals for optimum performance. Cutting grass silage at 2 - 3 months between cuts is too long and will result in low protein, low digestibility silages. Cut more often and you will grow more forage in a season of higher quality. You will have more production from your cows, use less concentrates and have fewer herd health issues.

Other areas to look at. Reseed regularly using the best digestibility grass seed varieties

available. Don't skimp on the fertiliser and check that other soil nutrients are in balance. Sulphur deficiency is a very common cause of poor fertiliser nitrogen utilisation and low protein levels in silage.

Other areas to look at. Reseed regularly using the best digestibility grass seed varieties

available. Don't skimp on the fertiliser and check that other soil nutrients are in balance. Sulphur deficiency is a very common cause of poor fertiliser nitrogen utilisation and low protein levels in silage.

Go for a

rapid wilt to 25% - 28% DM. Do a decent job of rolling and sealing the clamp. Prolonged wilts or air

present during the fermentation can both cause a lot of energy and protein to be lost. Always treat

with an effective, well proven silage additive. Back

to top

21. Why hasn't the silage additive worked?

In the vast majority of cases where the silage additive is suspected of not working it is down to management issues. There have been cases where applicator filters have been blocked and the silage additive hasn't been applied.

We do see plenty of cases where the silage additive selected was unsuitable

for the crop for example homo-lactic inoculants applied to 30% - 50% DM grass crops with high sugar levels,

destined for feeding in high temperature in the summer at very low feed out rates.

We do see plenty of cases where the silage additive selected was unsuitable

for the crop for example homo-lactic inoculants applied to 30% - 50% DM grass crops with high sugar levels,

destined for feeding in high temperature in the summer at very low feed out rates.

We also see situations where the additive used in difficult ensiling conditions was not up to the job.

But generally the problems on wet grass silages relate to soil and slurry contamination combined with high nitrogen levels. On dry silages problems are usually down to lack of consolidation on over wilted, dry, long chopped, stalky, high sugar silages in combination with inadequate clamp sealing, holes in sheets and low feed out rates in warm conditions.

For best results the clamp should well consolidated and sealed immediately paying attention to air tight sealing at the edges. Ideally the clamp should then be kept un-opened and air tight for several weeks. For a better understanding of the silage fermentation process see The Biology of Silage Preservation.Back to top

22. My silages are low in energy. Would a different silage additive help?

Probably not, if the fermentation is good and the silage isn't heating on the face. Chances are your grass crops are low in energy when they were cut. Cut earlier and more often. Re-seed with the latest High D-Value grass varieties. Check soil nutrients, lime, fertiliser levels etc. Having done that, then see if you can improve your ensiling techniques or silage additives. Back to top

23. Are there better silage additives out there?

Technology and our understanding of the silage making process continues to develop as do silage additives. All silage additives available in the UK have to conform to EU standards of quality, safety and efficacy. This means that they are safe to use and will show an improvement but still the capability of different silage additives varies widely. There are still silage additives widely sold that were developed in the 1980's and are still virtually the same spec. Ask yourself, technology has moved on, why haven't these additives?

Take a look at the new Ultra-Sile Range of Silage Additives

Take a look at the Ultra-Sile Silage Additive Range developed by Richard Webster Nutrition Ltd. This is a very versatile range of high specification silage additives which will continue to improve and develop as new developments occur. The Ultra-Sile Silage Additive Range is effective in preserving a wide range of forages including high dry matter grass silages, big bales, maize silage, wholecrop cereal silage and crimped cereals. Ultra-Sile Silage Additives are available to farmers throughout the UK.

Back to top24. Will an inoculant work in very wet and dirty conditions?

In very wet conditions there are situations where grass is so immature, low in sugar, high

in nitrogen and protein and so badly contaminated with soil, slurry and clostridia that it simply is

not possible to ensile and achieve a good fermentation under any circumstances.

In very wet conditions there are situations where grass is so immature, low in sugar, high

in nitrogen and protein and so badly contaminated with soil, slurry and clostridia that it simply is

not possible to ensile and achieve a good fermentation under any circumstances.

However a good high spec homo-fermentative inoculant will usually cope well with wet conditions and low sugar levels and would be our product of choice on wet grass silage.

Ultra-Sile Rapid and Ultra-Sile AD are high specification, multi-strain homo-fermentative additives and includes a finishing strain Lactobacillus paracasei which is capable of producing fructanase enzyme to produce additional sugars from fructans in order to complete the fermentation. We have found these products particularly effective in treating very wet grass silage in challenging situations and we have rarely seen a bad or butyric fermentation, even in some exceptionally difficult conditions.

25. What is the best silage additive to prevent silage going butyric?

Silages

which are in danger of going butyric are almost always, very wet, low in sugar, high in nitrogen and

protein, immature, with soil or slurry contamination and with high levels of clostridia present. Clostridia

which produce butyric acid, thrive in cold wet grass silages and produce butyric acid, break down protein

producing a variety of foul smelling amides, amines and ammonia.

Silages

which are in danger of going butyric are almost always, very wet, low in sugar, high in nitrogen and

protein, immature, with soil or slurry contamination and with high levels of clostridia present. Clostridia

which produce butyric acid, thrive in cold wet grass silages and produce butyric acid, break down protein

producing a variety of foul smelling amides, amines and ammonia.

Fortunately clostridia will not tolerate a very acidic environment. Any inoculant which drops the silage pH rapidly should prevent a butyric fermentation, provided that there are enough silage additive bacteria to control the fermentation when there are very high levels of clostridia present.

This type of grass silage will be high in buffering capacity and contain a lot of water, consequently a lot of acid is required to stabilise it and it will need to undergo a very extensive fermentation. Lactic is the strongest acid and homo-lactic fermentative strains will produce more acid using less sugar, faster under these conditions, so a conventional multi-strain lactic inoculant would be the product of choice.

I have hardly ever seen a butyric fermentation where

Ultra-Sile Rapid or Ultra-Sile AD have been applied at full strength

Multi-strain, high specification silage additives which apply a sufficiently high level of inoculant bacteria to dominate the fermentation and which contains an effective starter strain will cope with some very difficult challenges.

Ultra-Sile Rapid or Ultra-Sile AD would do particularly well since they include Lactobacillus paracasei. Lactobacillus paracasei can produce fructanase enzyme and produce more soluble sugars from fructans in order to complete the fermentation when sugar levels are very low. This is a better option than adding enzymes which may cause shrinkage, increased effluent etc if the pH doesn't stabilise.

Equally there would be little point using a preservative alone since the amount required would be too great and preservatives only become really effective once the pH has dropped to a low level. Of course a preservative could be used at a lower rate alongside an inoculant in really difficult situations where there are very high levels of clostridia from soil and slurry present, as an additional insurance. But to be fair I have hardly ever seen a butyric fermentation where Ultra-Sile Rapid or Ultra-Sile AD are applied. Back to top

26. My high lactic acid, low pH silage is causing acidosis?

In a well fermented silage sufficient acid needs to be produced to stabilise and preserve the silage.

Consequently high lactic acid should not necessarily be considered a bad thing. Much more preferable

to a silage where the fermentation ran out of sugars which restricted the fermentation

and where the silage turned butyric. In the latter case there will be less lactic acid and a higher

pH but the silage will have high dry matter losses, low sugars, be less palatable and support less animal

performance.

In a well fermented silage sufficient acid needs to be produced to stabilise and preserve the silage.

Consequently high lactic acid should not necessarily be considered a bad thing. Much more preferable

to a silage where the fermentation ran out of sugars which restricted the fermentation

and where the silage turned butyric. In the latter case there will be less lactic acid and a higher

pH but the silage will have high dry matter losses, low sugars, be less palatable and support less animal

performance.

Much more acid is required to preserve the silage if it is wet or has a high buffering capacity due to high levels of protein, nitrogen or soil contamination. A stable pH needs to achieved whether from lactic, acetic, propionic or other acids. With the notable exception of a couple of brew your own silage additives which have been widely sold in the UK, and which do have a reputation for producing very high lactic acid levels and taking the pH lower than is needed whether in homebrew or instant forms, most additives will not produce excessive amounts of lactic acid.

Lactic

acid can be minimised simply by efficient wilting to above 25% dry matter where ever possible. It should

however be argued that lactic acid is not the main or usual cause of acidosis in dairy cows.

Lactic

acid can be minimised simply by efficient wilting to above 25% dry matter where ever possible. It should

however be argued that lactic acid is not the main or usual cause of acidosis in dairy cows.

A proportion of most herds will be suffering from acidosis most of the time even if at a sub-clinical level where there are no symptoms other than a lack of performance, poor feed efficiency and a higher concentrate feed rate than is necessary for the milk yields produced. There are sound arguments for including Ostrea rumen buffer and a live yeast in diets as standard.

The main cause of acidosis is due to lack of scratch fibre when feeding very high digestibility forages or more frequently the feeding of excessive levels of starchy concentrates in an attempt to compensate for the low energy and low intake characteristics of many silages. Often the acidity of the silage is mistakenly blamed rather than the quality of the silage.

Lactic acid is a very good energy source for the cow and often much more lactic acid is created in the rumen when cows are fed large amounts of starch and are suffering from rumen acidosis, than is contributed by the silage. Beware of colour coded silage additive reports. A wet high lactic acid silage might contain over 200g/kg lactic acid, yet regularly we are told that maize silage is causing acidosis because the report shows lactic acid in the red with lactic acid at 60g - 70g/kg.

Some but not all live yeasts are very effective at mopping up excess lactic acid in the rumen. Biocell Yeast is particularly effective. If your cows are suffering from acidosis then there are lots of things that a good nutritionist can do to rectify the problem. Back to top

27. Why use anything other than Lactobacillus plantarum?

Lactobacillus plantarum is a perfectly good homo-fermentative strain which produces lactic acid efficiently.

It is not the only strain out there which produces good results and is not the most suitable for all

situations. All strains have their limitations and none work at their best throughout the whole range

of conditions found during the course of a fermentation.

Lactobacillus plantarum is a perfectly good homo-fermentative strain which produces lactic acid efficiently.

It is not the only strain out there which produces good results and is not the most suitable for all

situations. All strains have their limitations and none work at their best throughout the whole range

of conditions found during the course of a fermentation.

Trial work has shown that faster and more reliable fermentations can usually be achieved by using a multi-strain product. Some of the Pediococcus strains are better starters where pH is high, temperatures are often high and more oxygen is present. Completing the first part of the fermentation down to pH 5 very rapidly is particularly important in reducing protein break down and in reducing the multiplication of clostridia, yeasts, moulds and other spoilage organisms.

Other strains such as Lactobacillus casei and Lactobacillus paracasei are very rapid fermenters. Lactobacillus casei is very effective at removing oxygen from the clamp and therebye increasing speed of fermentation reducing losses and inhibiting spoilage organisms.

Whilst Lactobacillus plantarum is a very good finishing strain in situations where silages are very wet and low in sugar. Lactobacillus paracasei is capable of converting fructans to soluble fructose sugar when sugars are in short supply in order to complete the fermentation more effectively than Lactobacillus plantarum once all the soluble sugars are used up.

On dryer

silages above 26% dry matter or where aerobic stability and heating at the silage face is the main concern

we would use Lactobacillus casei in conjuction with hetero-fermentive strains or use hetero-fermentative

strains exclusively which tend to produce lower levels of lactic acid and are capable of producing higher levels

of volatile fatty acids (VFA's) including acetic acid and propionic acid which aid stability

and reduce heating at the silage face.

On dryer

silages above 26% dry matter or where aerobic stability and heating at the silage face is the main concern

we would use Lactobacillus casei in conjuction with hetero-fermentive strains or use hetero-fermentative

strains exclusively which tend to produce lower levels of lactic acid and are capable of producing higher levels

of volatile fatty acids (VFA's) including acetic acid and propionic acid which aid stability

and reduce heating at the silage face.

28. Are multi-strain better than single strain inoculants?

Dependant on the strains of inoculant bacteria used, multi-strain products can result in a faster fermentation than single strain products. Different strains work faster and are more efficient at different pH and oxygen levels, temperatures and osmotic pressures. The use of multiple strains has the advantage of a faster fermentation and more reliable results over a wide range of conditions. All Ultra-Sile inoculants are multi-strain.

29. How important are the number of bacteria applied?

The crop will contain a wide range of 'wild' micro-organisms.

Many of these are spoilage organisms and are undesirable. Inoculant bacterial strains multiply very rapidly

and at a faster rate than other microbes naturally present. The silage additive needs to be applied with

sufficient inoculant bacterial numbers to dominate the fermentation. This allows the inoculant to completely out

compete other microbes so that almost all the fermentation is carried out by the elite, efficient selected

strains supplied by the silage additive.

The crop will contain a wide range of 'wild' micro-organisms.

Many of these are spoilage organisms and are undesirable. Inoculant bacterial strains multiply very rapidly

and at a faster rate than other microbes naturally present. The silage additive needs to be applied with

sufficient inoculant bacterial numbers to dominate the fermentation. This allows the inoculant to completely out

compete other microbes so that almost all the fermentation is carried out by the elite, efficient selected

strains supplied by the silage additive.

The actual number of CFU's of bacteria needed to dominate a fermentation will depend on the effectiveness of the strains selected and the numbers of spoilage organisms present. Generally speaking 300,000 CFU / gram of forage is almost always adequate. Lower levels may be problematic and not always achieve an adequately controlled fermentation. 1 million CFU products may be used for particularly difficult situations but be aware that a 300,000 CFU multi-strain additive will often out perform a 1 million CFU single strain silage additive.Back to top

ULTRA-SILE SILAGE ADDITIVES

30. Are Ultra-Sile Silage Additives new?

The Ultra-Sile Range is the result of ongoing development of the range by Richard Webster Nutrition Ltd over more than twenty years. Products within the range are continually updated to take account of the latest technological developments. Back to top

31. Why haven't I heard about Ultra-Sile Silage Additives before?

The Ultra-Sile brand which is exclusive to Richard Webster Nutrition Ltd is widely sold within the UK. Emphasis is placed on providing a very high quality, high specification product at a very competitive price. Our low overhead costs allow us to offer more effective, higher specification products at lower prices. These products sell themselves on farmer to farmer recommendation without the need for a large advertising and marketing budgets and without the high cost of an on farm sales force.

32. How was the Ultra-Sile Range developed?

In 2002 RWN Ltd and a group of other independent agricultural merchants with a lot of experience in the UK silage additive market began to develop an improved range of silage additives. At that time there were over 50 silage additives registered on UK Forage Additives Register all backed by independent research trials.

Whilst

there had been a lot of progress in silage additive research very little of this new knowledge was being

adopted by manufacturers for the simple reason that most of them had made major investments in independent

research trials in order to get registration and also heavily invested in marketing. Any change to the

registered products would have meant re-doing all the trial work over several years at huge expense which

could not be justified commercially.

Whilst

there had been a lot of progress in silage additive research very little of this new knowledge was being

adopted by manufacturers for the simple reason that most of them had made major investments in independent

research trials in order to get registration and also heavily invested in marketing. Any change to the

registered products would have meant re-doing all the trial work over several years at huge expense which

could not be justified commercially.

Another issue was that when inoculants were widely introduced in the early 1980's they were designed to treat typical wet UK grass silages of the time at around 18% - 24% DM, often early cut with high levels of soil contamination and excess nitrogen which had a tendency to go butyric and run a lot of effluent. 20 years on, average silages in the UK had increased to an average of 33% DM largely as a result of the introduction of improvements in machinery, particularly mower conditioners. The problems had changed from a high risk of going butyric, to drier silage, less well consolidated and less well sheeted prone to heating and moulding on the face.

Most products on the UK market were homo-fermentative lactic acid type inoculants which whilst very effective on wet silage weren't well suited to modern drier silages. The fact that they all had independent trials showing that they were beneficial compared with no silage additive on wet silage in a well-managed research unit didn't mean that they were the best suited to a 40% DM poorly consolidated, late cut silage on a commercial farm.

We

knew that there was room for improvement and as a result the Gold Shake Range of silage additives was

developed. This was the pre-cursor to The Ultra-Sile Range. The range was developed and manufactured in conjunction with a major UK biotechnology company,

with a very experienced microbiologist with whom we could work closely and who was able to conduct all

the necessary lab trial work.

We

knew that there was room for improvement and as a result the Gold Shake Range of silage additives was

developed. This was the pre-cursor to The Ultra-Sile Range. The range was developed and manufactured in conjunction with a major UK biotechnology company,

with a very experienced microbiologist with whom we could work closely and who was able to conduct all

the necessary lab trial work.

Field trial work and testing has been carried out by Richard Webster over a number of years by splitting clamps on commercial farms and comparing directly against other silage additives, rather than against an untreated control. This approach of trialling under a wide range of conditions on real silage clamps, on local farms was able to quickly establish a clear advantage over other widely used silage additives.

We then went on to develop products specifically targeted at drier grass silages, whole crop silage and forage maize. Again by trialling against other silage additives on commercial farms we were able to demonstrate improvements in fermentation quality and aerobic stability.

Ultra-Sile silage Additives have over 10 years' worth of

field testing and trials on

local farms

After 10 years of rapid development and sales rocketing Richard Webster Nutrition launched the new Ultra-Sile Range of silage additives which is more comprehensive, more versatile and with some new refinements. Back to top

33. My current supplier says that Ultra-Sile Additives are not tested?

Some

silage additive manufacturers do rely very heavily on trials at independent research institutes from

the 1980's and 1990's as a means of selling their

product. Silage additives were normally trialled against a control with no additive. Much valuable work

was done in this way 20 - 30 years ago which has greatly extended our understanding

of silage making.

Some

silage additive manufacturers do rely very heavily on trials at independent research institutes from

the 1980's and 1990's as a means of selling their

product. Silage additives were normally trialled against a control with no additive. Much valuable work

was done in this way 20 - 30 years ago which has greatly extended our understanding

of silage making.

However showing that a silage additive is beneficial compared with no additive, on a particular grass silage, 20 years ago is not the same as comparing two products on very different silages under a wide range of conditions on commercial farms today. Silage making techniques have changed a lot since the 1980's and commercial farms have different challenges to silages produced for trial purposes at research institutes.

Ultra-Sile silage additives were originally based on products which had approval under the AIC Forage Additives Approval Scheme which required submission of at least 3 independent trials for each category of approval, improving fermentation, aerobic stability, effluent, ensiling losses, feed intake, digestibility, efficiency, live weight gain, milk production. The original formulations have undergone continued development resulting in the very advanced Ultra-Sile silage additives that we have today.

All strains of bacteria used are registered with European Food Safety Authority (EFSA) regulation 1831/2003

which covers silage additives which again requires extensive dossiers covering quality, safety, and efficacy.

All strains of bacteria used are registered with European Food Safety Authority (EFSA) regulation 1831/2003

which covers silage additives which again requires extensive dossiers covering quality, safety, and efficacy.

In addition Ultra-Sile silage additives are based on the Gold Shake Range of products which Richard Webster has trialled and field tested on commercial farms over 10 years in direct comparison with other commercial silage additives and with consistently outstanding results.

Ultra-Sile silage Additives have been tried and tested on local farms over 15 years

We have proven many times over, that silage additives work and that silage additives are cost effective. The challenge is to identify which formulations are most effective and under what conditions. Back to top

34. Does Ultra-Sile have any trial work?

All active ingredients used in Ultra-Sile have been fully trialled in accordance with EU1831(2003). In addition Ultra-Sile silage additives are based on the Gold Shake Range of products which Richard Webster has trialled on commercial farms over 10 years in direct comparison with other commercial silage additives and with consistently outstanding results. Back to top

35. Are Ultra-Sile silage additives fully approved and registered?

Ultra-Sile

silage additives are manufactured in the UK by a specialist manufacturer who is assured under the Feed

Materials Assurance Scheme and also with the Food Standards Agency under the Feed Hygiene Regulations.

FEMAS is based on HACCP principles, a system forming the bedrock of EU Food and Feed legislation.The

scheme is audited and certified by an independent certification body, in accordance with the internationally