Efficient Silage Making

Silage

making relies on anaerobic fermentation to convert sugars to organic acids. An anaerobic

fermentation

cannot take place in the presence of air. Where oxygen is present due to poor consolidation,

inadequate

sealing or where sheeting is delayed this process is slow, inefficient and wasteful resulting in

high dry matter losses. Often there will be top surface waste, a poorer fermentation in the top

third

of the clamp combined with with heating and spoilage on the face. This is especially so when

relying

on bacteria naturally present on the crop to carry the fermentation.

Fermentation can only begin when there is no air in the clamp

On the other hand the use of a silage inoculant or biological additive together with rapid filling, good consolidation and an effective air tight sealing will generally result in a very fast and efficient fermentation with minimal losses of dry matter. The result being a well fermented silage with minimal waste, more feed value and excellent intake characteristics. A silage inoculant or additive supplies selected elite strains of bacteria which are capable of rapidly fermenting sugars to acids much more efficiently than will take place in an uncontrolled fermentation. This could be likened to running a race with an Olympic athlete set against an 'old codger from down the village'.

Fast fermentation reduces losses, minimises waste and makes better silage

Always use an additive

Dropping the pH to below 5 in a matter of hours deactivates protease enzymes preventing protein breakdown and dramatically reduces the multiplication and activity of a wide range of spoilage organisms including clostridia, yeasts and moulds. With an inoculant, within a day or two the pit will be dropping towards 4 pH and becoming stable. This compares with up to 6 - 8 weeks for untreated clamps. A silage inoculant will rapidly drop the pH without wasting vast amounts of nutrients on heating the silage clamp for weeks on end. Whether or not an additive is used the fermentation cannot begin until there is no air in the clamp. That is why using good quality silage films and covers is so important.

Any air in the clamp will delay the fermentation and dramatically increase

losses.

Make sure that the clamp really is air tight

It

is not unusual to find silage clamps where the top metre or two of silage is low in quality

compared

to the bottom metre of the pit, due to impaired fermentation caused by oxygen presence during the

early

part of the fermentation. Often the these top layers are prone to heating on the face and are

contaminated

with mycotoxins. Not only will these

contaminated layers have reduced feed value and poor intake characteristics

they may cause the TMR or complete diet to heat. This can result in a loss of milk yield of up to

5

litres along with all sorts of knock on effects on cow health and fertility.

Inadequate sealing can represent a massive loss in output and profitability

Keeping Air out of Silage Clamps

The

amount of air in the pit depends on a wide range of factors. Firstly dry matter % is obviously

important. Below 25% DM most of the spaces between the particles of silage will be taken by

liquid. Above

30% DM unless the clamp is extremely well consolidated air can penetrate up to 1 - 2 metres from

the

surface or face with relative ease.

The

amount of air in the pit depends on a wide range of factors. Firstly dry matter % is obviously

important. Below 25% DM most of the spaces between the particles of silage will be taken by

liquid. Above

30% DM unless the clamp is extremely well consolidated air can penetrate up to 1 - 2 metres from

the

surface or face with relative ease.

Obviously wet, short chopped, leafy material, low in fibre will consolidate much better than dry, long chopped, stalky material.

Packing density is important. Ruppel, 1992 showed that dry matter losses halved from 20% to 10% when packing density was doubled. That is equivalent to saving 100 tonnes of silage for every 1000 tonnes clamped. More rolling with heavier machines on narrow tyres, rolling no more than 15cms of silage at a time will give the best consolidation.

Clamps should never be overfilled. Steep shoulders and slopes of more than 30o are almost impossible to roll. Wetter silage is much heavier than dry silage so putting some direct cut grass on top can be highly beneficial. The faster that filling is completed and the clamp is sheeted and sealed to exclude oxygen the better.

Covering Systems for sealing Silage Clamps

Richard

Webster has looked at hundreds of silage clamps every year for

the past 30 years. it is quite clear that some farms produce silage with virtually no visible

waste and excellent fermentation characteristics year in year out, whilst others make silage which

has

top waste and a very average fermentation most of the time.

Richard

Webster has looked at hundreds of silage clamps every year for

the past 30 years. it is quite clear that some farms produce silage with virtually no visible

waste and excellent fermentation characteristics year in year out, whilst others make silage which

has

top waste and a very average fermentation most of the time.

This is probably one of the reasons why the top 10% of farms have always made double the profit per cow compared with the bottom 10%. Attention to detail. Basically there is nothing that the best silage makers are doing that can't be done by the whole industry.

Stating the obvious, oxygen will only stay out of the clamp if there is an impermeable, air tight barrier between the silage and the outside air. If the edges aren't air tight, if there are holes in it, if there are air pockets under it, if there are gaps at the edges, if it is permeable to air then air will get through. On outside pits where the wind constantly changes in pressure much more air will get through.

If the clamp does not have a truly air tight seal, then there will be losses and waste

Both

standard black silage sheets and the new thin clear polythene clamp films which have recently

entered

the market are both made of polythene are permeable to oxygen. In fact black plastic sheets have

been shown to be capable of transmitting around 2 litres of oxygen per square

metre per day across the whole sheet and clear polythene cling film sheets around 7 litres of

oxygen

/ m2 / day. Even putting several sheets on will allow significant amounts of oxygen

into the clamp.

When we consider that average dry matter of grass silage over 30 years has risen from 22% to 32%, we make more dry wholecrops and maize silages, we have more outside clamps, we use far fewer tyres, we have less labour available to do a proper job of sealing the clamp, then it is not surprising that despite the massive technological improvements in silage additives, silage making techniques, machinery, nets, silage films and silage covers and gravel bags we still have a major problem with waste and excessive dry matter losses in silage clamps. Good quality silage sheets and covers really do make a massive difference to losses. Click here to see how to sheet and seal a silage clamp properly. Take care to avoid accidents with silage pits.

Despite massive technological improvements, we still have a major problem with excessive losses in silage clamps

Fortunately there is a cost effective solution. For several years now Richard Webster Nutrition has been promoting a completely new type of sheet, Low Transmission Oxygen Barrier Film from Passion Ag and Silostop.

Silage Covering Systems

Low transmission

oxygen barrier film was

developed in Italy by a joint effort between a leading plastic film manufacturer and University

scientists.

This was at the request of Italian farmers for assistance from the University for ways to improve

their

silage quality and minimise the risk of moulds in the silage entering the food chain. This was

particularly

important when producing certain cheeses. Oxygen Barrier Film has been scientifically proven

by a number of research centres in the UK, the USA and across Europe.

Low transmission

oxygen barrier film was

developed in Italy by a joint effort between a leading plastic film manufacturer and University

scientists.

This was at the request of Italian farmers for assistance from the University for ways to improve

their

silage quality and minimise the risk of moulds in the silage entering the food chain. This was

particularly

important when producing certain cheeses. Oxygen Barrier Film has been scientifically proven

by a number of research centres in the UK, the USA and across Europe.

Oxygen Barrier Film

The Passion Ag and Silostop low transmission oxygen barrier films are quite different from other clear cling film type sheets which are made of polythene and which do transmit oxygen. These oxygen barrier films are just as effective as standard cling film type sheets at clinging to the silage surface but unlike other clear films or black plastic sheets, oxygen barrier films do prevent the transmission of any significant amounts of oxygen into the silage surface.

"Oxygen Barrier Film has been the most important development in silaging during the past 45 years. It has given us the means to exclude oxygen out of the silage clamp " - Keith Bolsen, Professor Emeritus Kansas State University.

The ONLY true Oxygen Barrier Films for Silage

Types of Silage Sheets available in the UK

There are many branded silage sheets and cling film products available in the UK, many claiming to be as good, better or cheaper than the Silostop or Passion Ag low oxygen transmission silage films. This can be very confusing. Basically silage sheets fall into 3 distinct categories.

- Black Plastic sheets made from polythene, usually recycled, coloured black to protect them from sunlight. Black plastic is water proof but is porous to air transmitting large volumes of air into the silage clamp especially on windy sites.

- Cling Film products made from clear virgin polythene. These silage cling film products are thinner than black plastic sheets sealing better at the edges and forming to the silage more effectively than the thicker black plastic. They are waterproof, but transmit several times more air than black plastic sheeting and are easily damaged.

- Low Transmission Oxygen Barrier Films are almost as strong as black sheets and almost as thin as cling film products. As well as being waterproof these films are a genuine oxygen barrier transmitting minimal amounts of oxygen even on windy, exposed sites. These are the only silage sheets or silage films with extensive independent research demonstrating their ability to exclude oxygen, improve silage fermentation characteristics and consistently reduce silage losses compared with other sheeting systems.

Silage losses occur when oxygen is not effectively excluded during the fermentation

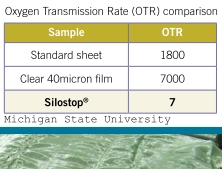

Tests

on Silostop at Michigan State University forage research centre showed dramatic reductions in

oxygen

transmission compared with other silage sheets. Silostop oxygen barrier film has proven extremely

effective

at reducing or eliminating top waste on grass silage, wholecrop, maize and crimped cereals on

commercial

farms. Low transmission oxygen barrier films

should not be confused with cheap low density polythene films. Oxygen barrier

films

have been shown in over 40 trials to reduce dry matter losses by up to 50% in the top layers of silage.

Tests

on Silostop at Michigan State University forage research centre showed dramatic reductions in

oxygen

transmission compared with other silage sheets. Silostop oxygen barrier film has proven extremely

effective

at reducing or eliminating top waste on grass silage, wholecrop, maize and crimped cereals on

commercial

farms. Low transmission oxygen barrier films

should not be confused with cheap low density polythene films. Oxygen barrier

films

have been shown in over 40 trials to reduce dry matter losses by up to 50% in the top layers of silage.

Oxygen Barrier Films are more than 100 times better than conventional clear plastic silage films at preventing oxygen transmission

Check out the low oxygen transmission rates and research on the Passion AG OB Film Brochure.

Oxygen Barrier films are generally used underneath a conventional black plastic sheet or under a close weave protective anti-UV net to protect them from UV light. Since the objective is to exclude oxygen particular attention should be paid to sealing the edges and to protecting the sheet from damage, making sure that all silage sheets, covers and protective nets are secure and that edges are well sealed. Use gravel bags on seams, shoulders and edges and for best results weight the sheets with tyres or lorry tyre sidewalls across the whole silage clamp surface.

Low Transmission Oxygen Barrier Films Reduce Silage Losses

Trials with Oxygen Barrier Film at the University of Nottingham showed that where

oxygen barrier

film was used instead of conventional black plastic sheeting, silage judged to be inedible and

discarded

on 1700 tonne silage clamps, was reduced from 5.9% to 0.1% or from 100 tonnes per clamp to 1.7

tonnes.

Trials with Oxygen Barrier Film at the University of Nottingham showed that where

oxygen barrier

film was used instead of conventional black plastic sheeting, silage judged to be inedible and

discarded

on 1700 tonne silage clamps, was reduced from 5.9% to 0.1% or from 100 tonnes per clamp to 1.7

tonnes.

Assuming an additional cost of around £300 for oxygen barrier film and a cost of £30 / tonne for silage this would save more than £2500 per clamp giving a return on investment of around 8:1 even before taking into account improvements in silage feed quality and animal performance.

Low Transmission Oxygen Barrier Film is much more effective than Cling Film

Apple slices shrink wrapped in low transmission oxygen barrier film preserved well even after 6 months in warm conditions.

Apple slices shrink wrapped in low transmission oxygen barrier film preserved well even after 6 months in warm conditions.

The same apples shrink wrapped in standard polythene silage cling film quickly discoloured and were completely rotted and decomposed within a few weeks.

No wonder that a quality oxygen barrier reduces dry matter losses and top waste in silage.

Not all Oxygen Barrier Films are equal

A comparison of Passion Yellow Oxygen Barrier Film versus another widely available Oxygen Barrier Film clearly demonstrated that not all oxygen barrier films are equal.

A comparison of Passion Yellow Oxygen Barrier Film versus another widely available Oxygen Barrier Film clearly demonstrated that not all oxygen barrier films are equal.

The Passion Yellow Film prevented deterioration apples much more effectively than the other film.

We strongly recommend Passion Yellow Oxygen Barrier film for use on all silage pits. Grass, wholecrop, maize and crimped cereals.

Passion Yellow Oxygen Barrier Film has been shown to out perform other films

A recent review of over 50 trials comparing oxygen barrier films with standard polythene clearly demonstrated not only reduced dry matter losses but also improved aerobic stability with the top layers of silage staying cool for 60 hours longer.

Oxygen Barrier can improve aerobic stability by up to 2.5 days

45 micron low transmission oxygen barrier is available either as Passion Gold, Passion Yellow or Silostop Orange Silage Sheets. Whilst strength is comparable to conventional 100 micron black plastic sheets, 45 micron oxygen barrier films are much better at moulding and clinging to the silage surface and much better at sealing at the edges than conventional 100 micron black silage sheets.

Passion Yellow oxygen barrier films and Silostop Orange oxygen barrier films are designed for use either under standard black plastic silage sheets or under a close weave anti-UV protective net. We consider these to be the best option currently available for effectively sealing a silage pit.

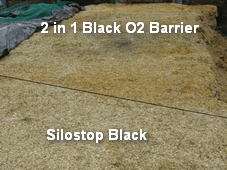

Passion Yellow on Black or Silostop Max are new 2 in 1 films. These thicker 80 micron oxygen barrier sheets are designed for use where only one sheet is used with or without a net. These 2 in 1 oxygen barrier sheets offer a convenient option for use where a single sheet is preferred for ease of handling.

For best results, our preferred option is to use 45 micron Oxygen Barrier Film, then fold over side sheets and then apply a conventional black sheet. Cover with a protective net. Use gravel bags around the edge of the pit then cover with lorry tyre sidewalls, touching across the whole surface. This generally produces a completely air tight seal with no top waste and greatly reduced dry matter losses in the top metre of silage.

For best results, our preferred option is to use 45 micron Oxygen Barrier Film, then fold over side sheets and then apply a conventional black sheet. Cover with a protective net. Use gravel bags around the edge of the pit then cover with lorry tyre sidewalls, touching across the whole surface. This generally produces a completely air tight seal with no top waste and greatly reduced dry matter losses in the top metre of silage.

Silage Oxygen Barrier Film Testimonials:

A R Cox & Son, Manor Farm Staffordshire and JM & SE Jackson, Longpools Farm, Shropshire

For further information including scientific trial data, product information, and

Frequently

Asked Questions download the Passion AG OB Film Brochure.

Use a genuine oxygen barrier film as a matter of course for superb quality silage

Oxygen Barrier Films Reduce Losses in Silage Clamps

Oxygen Barrier Films can be used in various combinations with other covers either with or without tyres. One of the best combinations is Oxygen Barrier Film, covered with Protective Silage Nets with gravel bags round the edges and RWN Lorry Tyre Sidewalls to apply an even weight across the pit. They make the best and most effective silage pit covers dramatically reducing top waste on silage pits.

As well as being effective on a wide range of ensiled crops oxygen barrier films are particularly useful for controlling spoilage and top waste on moist feeds as can be seen from the picture here.

Feed value savings from using oxygen barrier films are far greater than

the additional cost

compared with cheaper clear silage cling films

A clamp of high quality

forage is very valuable. A little additional time and effort in sealing the

clamp together with a little additional investment in additives, oxygen barrier films, sheets, nets and covers can make

all

the difference between a below average product with high dry matter losses, poor fermentation,

mycotoxins,

spoilage and heating on the face, or a superb, stable, feed with excellent intake characteristics

capable of supporting very high levels

of performance and milk yields with less reliance on concentrates.

A clamp of high quality

forage is very valuable. A little additional time and effort in sealing the

clamp together with a little additional investment in additives, oxygen barrier films, sheets, nets and covers can make

all

the difference between a below average product with high dry matter losses, poor fermentation,

mycotoxins,

spoilage and heating on the face, or a superb, stable, feed with excellent intake characteristics

capable of supporting very high levels

of performance and milk yields with less reliance on concentrates.

Protective Nets and Gravel Bags

Gravel Bags

Gravel bags are highly beneficial especially on outside pits. They have a much heavier footprint than tyres and mould to the silage better along walls, shoulders and at the pit edges. Gravel bags are 1 metre in length when filled and weigh around 25kg.

Whilst lorry tyre sidewalls offer the best option for weighting the whole clamp surface to reduce surface waste. Gravel bags are much more effective than tyres when used against walls, on the ground and along the face. Gravel bags can also be used across the pit at 3 metre intervals as an alternative to tyres.

RWN Protective Silage Covers and Nets

We offer a wide range of Protective Silage Covers and Nets. These are designed to protect plastic silage sheets and films from holes caused by birds, cats and dogs as well as from any other accidental physical damage which would allow entry of oxygen or water in to the silage pit.

Oxygen barriers are not airtight if they have holes in them.

Protect sheets with silage covers or nets and weight the surface for best results.

Anti-UV nets mould

well

to the silage and can be used directly on top of the clear orange oxygen barrier

film avoiding the need to use a black plastic sheet to protect the film from sunlight. Nets are

much easier to use than tyres.

Anti-UV nets mould

well

to the silage and can be used directly on top of the clear orange oxygen barrier

film avoiding the need to use a black plastic sheet to protect the film from sunlight. Nets are

much easier to use than tyres.

Anti-UV protective nets are close weave, non-slip and are relatively impermeable to wind pressure changes making them a much better option than the widely used open weave silage nets.

Trial work at Leeds University has clearly demonstrated that close weave Anti-UV nets are much more effective in reducing oxygen transmission into the clamp than open weave, see-through nets and covers. The protective close weave anti-UV net reduced DM losses in the top 30cms of silage due to oxygen transmission from 35% to 8.2% when used on top of two black sheets.

Anti-UV Protective Nets are much more effective than open weave nets

Anti-UV close weave protective silage nets have many advantages over most other silage nets. They are wind resistant reducing oxygen transmission when used over standard plastic films or silage sheets. They are very flexible, forming well to the silage and are easier to handle. They can be used directly over plastic film without need for a black sheet. They are non-slip so gravel bags are less prone to sliding off the slopes. Most importantly anti-UV protective silage nets are much safer to walk on than most open weave nets widely available in the UK.

UV Nets and Advanced Fleece Covers are Non-Slip and safer than most open weave nets

Advanced Fleece Silage Covers : These new, advanced, fleece silage covers are thicker and heavier than conventional woven polypropylene nets.

Advanced Fleece Silage Covers : These new, advanced, fleece silage covers are thicker and heavier than conventional woven polypropylene nets.

These fleece silage covers are much more wind resistant, more bird proof and don't move on the silage clamp. The non-fray design which hugs silage contours, offers excellent protection against birds and other physical damage.

They are longer lasting than conventional green woven protective covers. The extra thickness gives greater protection against pin-holing of sheets caused by claws of birds and small mammals which may happen with some conventional protected covers.

The unique structure is not affected by wind and repels water. If damaged by machinery they can also be easily repaired. Passion Fabric Hooks can be used for both repairs and to hold the fleece covers in place over large areas.

The new Passion Fleece Covers are supplied in 6m widths and in various lengths. They can be secured with minimal overlaps using velcro patches or gravel bags. If put length ways on the pit they can be rolled onto 6m lengths of plastic drainage pipe for easy handling.

Fleece Covers are more applicable in situations where an oxygen barrier film is used without a black sheet and also where only minimal amounts of gravel bags, tyres and lorry tyre sidewalls are used to weight the silage pit surface.

Silostop SupaCova Premium Open Weave Nets: These are a premium net which will protect plastic silage sheets and oxygen barrier films from damage preventing ingress of water and oxygen into the silage clamp. They are very durable and bird proof.

BETTER SILAGE, REDUCED FEED COSTS, MORE MILK AND LESS HASSLE

More Effective Clamp Sealing Systems

Always use an effective Silage Additive. For advice on Making Better Silage and reducing feed costs, contact Richard Webster.