Silage

Additives and Quality Forage

Silage

Additives and Quality Forage

The Ultra-Sile Silage Additive Range is effective in preserving a wide range of silages, whether clamp, big bale, maize or whole crop.

We at RWN believe and can demonstrate both the benefits of using an effective silage additive to achieve a good fermentation along with the costs associated with not using a silage additive.

Years of research clearly show the financial benefits of using a proven inoculant based silage additive as routine when ensiling all types of silage irrespective of weather conditions.

Quality forage forms the basis of any high yielding dairy diet

Adopting New Technology - The Challenge

In times of financial hardship there is always resistance to adopting new technology which is often seen as a cost, rather than as a means of increasing profitability. Biological silage additives and forage inoculants have been around for well over 30 years, yet still many UK dairy farmers still don't use them on all their crops despite the clear financial benefits of doing so.

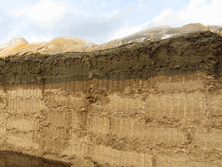

Traditionally much silage has not been harvested until it is past its best with lower digestibility and protein levels. Once grass is heading much of the nutritional value of the crop is already lost. Typically grass can lose 2 - 3 percentage points of protein and 2 - 3 units of digestibility in a week in a standing crop and much more in a lodged crop. Few farmers would consider grazing this mature grass, since they know that it has no milk in it, yet they are quite happy to spend money making it into low quality silage.

Traditionally much silage has not been harvested until it is past its best with lower digestibility and protein levels. Once grass is heading much of the nutritional value of the crop is already lost. Typically grass can lose 2 - 3 percentage points of protein and 2 - 3 units of digestibility in a week in a standing crop and much more in a lodged crop. Few farmers would consider grazing this mature grass, since they know that it has no milk in it, yet they are quite happy to spend money making it into low quality silage.

Recently we have seen a move in the UK to multi-cut silage systems, taking 3 - 5 cuts in a season. This younger, high digestibly, higher protein, lower sugar material is generally more difficult to ensile but has much greater feed value and will allow higher animal performance on lower levels of concentrate.

Far better to cut at the optimum D-value and invest in a silage additive in order to guarantee a well fermented clamp of high nutritive value

Conserved forage makes up well over 50% of the ration during the winter months on most UK dairy farms. To achieve optimum feed efficiency, production levels and profitability, it is essential that all silage ferments well and retains as much of the nutrition of the growing crop as possible.

Why use a Silage Additive?

The

case for using an effective biological inoculant based silage additive, irrespective of weather conditions

is proven beyond doubt. Put quite simply, "If you use a silage additive you will generate

more profit". This

applies whether you are using a grass silage additive, a wholecrop additive or

a maize additive. It is important to treat all fermented crops with a silage additive in order conserve

as much feed value as possible in order to maximise profits.

The

case for using an effective biological inoculant based silage additive, irrespective of weather conditions

is proven beyond doubt. Put quite simply, "If you use a silage additive you will generate

more profit". This

applies whether you are using a grass silage additive, a wholecrop additive or

a maize additive. It is important to treat all fermented crops with a silage additive in order conserve

as much feed value as possible in order to maximise profits.

Using a silage additive does not means that normal good ensiling practice or clamp management is any less important, on the contrary your silage clamp will contain a higher value product containing more nutrients, attention to detail is paramount.

Silage Additives will not compensate for poor ensiling practices. For best results always ensile at optimum maturity, moisture content and chop length. Fill the clamp quickly, consolidate well and seal it so that it really is air tight. Use oxygen barrier film, protect sheets with protective woven covers and weight the entire silage clamp surface with straw bales or lorry tyre sidewalls.

It is important that you select the best silage additive for the job. Silage is a valuable asset.

How do Biological Silage Additives and Inoculants work?

In an un-treated silage clamp, wild bacteria, yeasts and moulds

grow on the crop consuming crop nutrients. Some of these bacteria in anaerobic conditions do ferment

sugars and produce acids and will eventually conserve the crop. This natural uncontrolled

fermentation process is slow and inefficient, generating high temperatures,

high losses of dry matter and crop nutrients.

In an un-treated silage clamp, wild bacteria, yeasts and moulds

grow on the crop consuming crop nutrients. Some of these bacteria in anaerobic conditions do ferment

sugars and produce acids and will eventually conserve the crop. This natural uncontrolled

fermentation process is slow and inefficient, generating high temperatures,

high losses of dry matter and crop nutrients.

An effective biological silage additive will contain, a range of specially selected strains of bacteria designed to inoculate the clamp and dominate the fermentation. These selected strains rapidly reduce the pH of the crop with minimum nutrient loss. Inoculant bacteria are generally around twice as efficient at converting sugar to acid than those bacteria naturally present.

Most silage additives were traditionally based on homo-fermentative strains of bacteria which produce lactic acid only, a strong acid which very rapidly stabilises the clamp at around 4.0 pH with minimal heating or nutrient loss. The process is much faster and more efficient than a natural fermentation and completed in days rather than weeks. The most effective silage additives will contain several different strains of bacteria to cope with a wide range of dry matter, temperatures, pH and nutrient conditions. Multi-strain inoculants are in most situations faster, more reliable and more efficient than single strain inoculants.

Average dry matter of UK silages have increased over the years from around 22% DM in the early 1980's to over 30% DM currently. This has led to increased issues with aerobic spoilage and heating at the silage face.

Average dry matter of UK silages have increased over the years from around 22% DM in the early 1980's to over 30% DM currently. This has led to increased issues with aerobic spoilage and heating at the silage face.

Consequently many additives now include hetero-fermentative strains of inoculant bacteria. These are capable of producing acetic and propionic acids and are much more effective at controlling heating in dry silages than lactic acid only strains.

Our Ultra-Sile range is continually updated to take full advantage of the very latest technological advances. Ultra-Sile Dry, Ultra-Sile HiDri and Ultra-Sile Maize include a very advanced new strain of bacteria, Lactobacillus caseii which is not only a very fast fermenter but is also very effective at removing oxygen from the clamp during the first few hours of the fermentation. Fermentation cannot start until oxygen is removed.

These products speed up the fermentation process reduce dry matter and energy losses, reduce protein breakdown and inhibit the growth of spoilage organisms, yeasts and moulds. These advanced inoculants use the very latest technology and show clear advantages over many other inoculants in terms of fermentation efficiency, intake characteristics, levels of toxins, nutritional quality of the silage and face stability.

These products speed up the fermentation process reduce dry matter and energy losses, reduce protein breakdown and inhibit the growth of spoilage organisms, yeasts and moulds. These advanced inoculants use the very latest technology and show clear advantages over many other inoculants in terms of fermentation efficiency, intake characteristics, levels of toxins, nutritional quality of the silage and face stability.

Some additives include some additional enzymes such as cellulase, xylanase, or hemicellulase. The aim being to convert fibre to sugars to feed the inoculant bacteria. In practice most inoculant bacteria produce plenty of enzymes themselves and sugar levels are normally more than adequate. Much more important is the levels and combinations of specific strains of inoculant bacteria applied.

How

an

Additive Makes Better Silage?

How

an

Additive Makes Better Silage?

The benefits of using silage additives are now well established beyond doubt, through a wealth of trial work throughout the World, as well as years of observation in the field on commercial farms. Typically the use of an inoculant will speed up and improve the efficiency of the fermentation, rapidly reaching a stable pH.

Dry matter losses are reduced by on average around 4.5%, which is equivalent to an additional 45 tonnes of silage in a 1000 tonne clamp

Effluent levels are usually less than on untreated silage. Due to the rapid stabilisation of the clamp the amount of protein broken down to free amino acids is greatly reduced. Treated silage will typically contain between 50% and 75% more bound, true protein than untreated silage. These proteins are more available to the animal and more readily used for production by the animal. Retained sugar levels are likely to be higher and in some cases more than double the levels found in untreated silage. IBER's work on High Sugar Grasses has clearly demonstrated the benefits to livestock performance from feeding forages which are higher in sugar.

What Benefits will Livestock get from a Silage Additive?

Additive

treated silages are more palatable. They contain more sugar and fermentable energy. They contain more

better quality protein. Not surprisingly animals consistently perform better when fed additive treated

silages.

Additive

treated silages are more palatable. They contain more sugar and fermentable energy. They contain more

better quality protein. Not surprisingly animals consistently perform better when fed additive treated

silages.

Dairy cows can typically produce 1.0 - 1.5 litres more milk per day. Beef cattle, dairy heifers and youngstock will generally increase live weight gains by up to 30%.

Typically using a silage additive can easily result in a return on the investment of up to 10:1, or to put it another way, failure to invest £1000 in additive will probably cost you up to £10000 in lost income. Investing a similar amount in buying extra concentrates will not return this level of return on investment.

Issues facing Silage makers?

Greater use of contractors, more rapid pit filling with larger machinery,

reduced nitrogen application, more attention to avoiding soil and slurry contamination,

faster wilting and dryer silages has meant

that butyric silages are much less common.

Greater use of contractors, more rapid pit filling with larger machinery,

reduced nitrogen application, more attention to avoiding soil and slurry contamination,

faster wilting and dryer silages has meant

that butyric silages are much less common.

The use of a silage additive is still extremely important, not as an insurance against bad weather but in order to improve the efficiency and speed of fermentation, to retain nutrients and to increase animal performance. Our aim is to produce silage as close in feed value to the growing crop as possible.

Bigger machinery and use of contractors has created a new problem. Often silage comes in so fast that it is impossible to consolidate the silage sufficiently. Dry, poorly consolidated silage is much more prone to heating during the fermentation as well as to aerobic instability, heating and moulding on the silage face during use. This is a particular problem with mature, high dry matter crops containing plenty of retained sugar. For best results it is important to fully understand the process of silage fermentation which is well described in The Biology of Silage Preservation.

Aerobic Instability - Controlling Heating in Silages

Silage

making is an anaerobic fermentation process, there is no substitute for good consolidation and effective

sealing of the silage clamp. As a guide, if you are able to push your fingers more than 1cm into a silage face

it is insufficiently rolled.

Silage

making is an anaerobic fermentation process, there is no substitute for good consolidation and effective

sealing of the silage clamp. As a guide, if you are able to push your fingers more than 1cm into a silage face

it is insufficiently rolled.

Doubling the density of the silage has been shown to reduce in clamp dry matter losses from 20% to 10%. This explains why the bottom third of the clamp is often more stable, better fermented and feeds better than the top third. More time spent on rolling, additional clamp space to avoid overfilling and use of a low oxygen transmission Oxygen Barrier Film is well worth the investment.

Aerobic stability of the top metre of silage can also be greatly improved by using Protective Nets to protect the plastic silage sheet. Best results can be achieved by then adding weight to the entire silage pit surface to consolidate the surface of the pit and to prevent nets and sheets from lifting in the wind. This can best be achieved by use of Lorry Tyre Sidewalls. A little additional investment in sealing the clamp can make a big difference to both silage quality and spoilage.

Cutting

younger, higher D-Value material will help consolidation and reduce heating. Mature, higher fibre, higher

dry matter grass silages, low in crude protein and high in sugars will have more potential to heat on

the face.

Cutting

younger, higher D-Value material will help consolidation and reduce heating. Mature, higher fibre, higher

dry matter grass silages, low in crude protein and high in sugars will have more potential to heat on

the face.

Even on well consolidated high dry matter silages, there will be a tendency to heat, unless usage is rapid. Having gone to great lengths to grow quality forages with good feed value and a high sugar content, we must minimise both fermentation losses and loss of these sugars due to aerobic activity of yeasts and moulds at the silage face.

Most biological silage additives on the market in the UK today are still based on homo-fermentative lactic acid producing bacteria. These were originally developed over 40 years ago when silages were poorly wilted, often below 20% dry matter, high in nitrates and crude protein as a consequence of heavy applications of ammonium nitrate fertiliser. The main objective then was to prevent the silage from going butyric.

Lactic acid is effective at rapidly dropping the pH of a silage efficiently and with minimum nutrient losses, but in dryer silages which are prone to heating on the face lactic acid is rapidly broken down by spoilage organisms. Lactic acid based inoculants are not the best choice when it comes to dryer silages above 25% - 27% dry matter.

Are Most Silages too Dry for Standard Silage Additives?

Average

UK grass silages are now well over 30% dry matter. Silages above 25% DM are prone to heating. Lactic

acid based inoculants are not particularly effective in controlling heating in well preserved drier grass silages, whole crop or maize.

Average

UK grass silages are now well over 30% dry matter. Silages above 25% DM are prone to heating. Lactic

acid based inoculants are not particularly effective in controlling heating in well preserved drier grass silages, whole crop or maize.

Where heating occurs, spoilage organisms, in particular lactate assimilating yeasts feed off the lactic acid using it as an energy source and effectively remove the preservation of the silage.

Consequently we now recommend standard lactic only silage additives for use only with forages below 25% to 28% DM. Below 25% dry matter, silages undergo an extensive fermentation and require a lot of acid to effectively preserve them. A multi-strain homo-fermentative biological silage additive such as Ultra-Sile Rapid which rapidly produces lactic acid will be the most effective means of stabilising a wet silage with minimum dry matter losses.

On dryer silages above lactic acid only products can no longer be considered the best silage additive treatment. For more information on profitable silage making check our Silage Making and Additives FAQ's page.

Ultra-Sile Advanced New Additives for Higher Dry Matter Silages

The

Ultra-Sile range of Silage Additives developed by Richard Webster Nutrition incorporates advanced new products designed to be used for enhanced face stability and reduced heating.

The

Ultra-Sile range of Silage Additives developed by Richard Webster Nutrition incorporates advanced new products designed to be used for enhanced face stability and reduced heating.

These additives include several hetero-fermentative strains which have the ability to produce a range of acids including acetic acid, propionic acid and other anti-microbials rather than lactic acid alone.

Our new Lactobacillus casei strain has the ability to drop the pH quickly whilst efficiently absorbing oxygen to starve spoilage organisms. L. casei also produces diacetyl which very effectively inhibits spoilage and heating.

Ultra-Sile Dry, Ultra-Sile Premium, Ultra-Sile HiDri, Ultra-Sile Maize and Ultra-Sile Arable additives, contain these new advanced inoculant strains offering a massive advantage over most other widely used lactic acid based silage additives in preventing heating on silages.

These new high

specification silage additives, over a number of years have been shown to be far more effective in maintaining

face stability and reducing nutrient losses than other biological additives currently available in dryer silages whilst having the additional advantage that they also cope relatively well with wetter silages.

These new high

specification silage additives, over a number of years have been shown to be far more effective in maintaining

face stability and reducing nutrient losses than other biological additives currently available in dryer silages whilst having the additional advantage that they also cope relatively well with wetter silages.

Preservatives and Inoculant Preservative Combination Products

Chemical preservatives and acids can be effective in treating dry silages but they are generally more costly than the latest inoculants and no more effective. On wetter silages much higher levels of preservative are required to be effective.

Chemical preservatives and acids have rarely result in improved animal performance. The use of chemical preservatives can also be much less effective in preserving lower dry matter silages due to the dilution effect on the preservative.

RWN's

Ultra-Sile Dual-Action and Ultra-Sile Liquid Combined are combination products which have the advantage

of including both inoculant bacteria and chemical food preservatives such as Potassium Sorbate, Sodium

Benzoate, Sodium Nitrite or Sulphites which can be effective in restricting the development of yeasts

and fungi.

RWN's

Ultra-Sile Dual-Action and Ultra-Sile Liquid Combined are combination products which have the advantage

of including both inoculant bacteria and chemical food preservatives such as Potassium Sorbate, Sodium

Benzoate, Sodium Nitrite or Sulphites which can be effective in restricting the development of yeasts

and fungi.

Chemical preservatives are effective at controlling spoilage organisms once the silage has fermented down to a stable pH but much less effective at the start of the fermentation at higher pH levels.

Combination products which include a preservative together with an effective silage inoculant to rapidly drop the pH of the silage will generally be much more effective at preventing spoilage organisms from multiplying than a preservative or acid only additive.

Whilst more costly than a straight inoculant these new combination silage additives can be very effective where additional face stability is required. Ultra-Sile Liquid Combined and Ultra-Sile Dual-Action silage additives can be particularly effective where fermentation conditions are difficult and where spoilage organisms, soil, moulds and clostridia are brought in with the crop and where particularly good face stability are a requirement.

In the vast majority of situations Ultra-Sile inoculant only products are as effective and at a lower cost.

The Ultra-Sile Additive Range

Richard

Webster has spent over 40 years working with a wide range of forage

additives. The Ultra-Sile Range uses combinations of multiple strains of bacteria which

have been repeatedly shown in trials to out-perform single strain products.

Richard

Webster has spent over 40 years working with a wide range of forage

additives. The Ultra-Sile Range uses combinations of multiple strains of bacteria which

have been repeatedly shown in trials to out-perform single strain products.

The new Ultra-Sile Silage Additive Range builds on this experience and is the result of over 20 years of development work. The range incorporates new biological products for treating higher dry matter silages including grass silage, forage maize, wholecrop cereals and crimped cereals.

Ultra-Sile Silage Additives have been extensively trialled under commercial conditions over a number of years and have proved to offer extremely effective solutions to cover a very wide range of fermentation conditions. Based on many years experience working with silage additives in the field on UK dairy farms, we believe that the silage additive range that we offer is second to none.

Ultra-Sile arguably the Most Comprehensive, Most Cost Effective and

Most Advanced

Range of

UK Silage Additives

The Ultra-Sile Silage Additive Range is effective in preserving a wide range of forages including high dry matter grass silages, big bales, maize silage, wholecrop cereal silage and crimped cereals. Ultra-Sile Silage Additives are available to farmers throughout the UK.

Ultra-Sile Rapid and Ultra-Sile AD are extremely effective high specification multi-strain

inoculants for treating wet grass silages below 28% dry matter. These state of the art silage additives reduce

fermentation losses by encouraging a very rapid, cool homo-lactic fermentation.

Ultra-Sile Rapid and Ultra-Sile AD are extremely effective high specification multi-strain

inoculants for treating wet grass silages below 28% dry matter. These state of the art silage additives reduce

fermentation losses by encouraging a very rapid, cool homo-lactic fermentation.

Where sugars are Low Lactobacillus paracasei is able to produce fructanase enzyme to convert fructans into soluble fructose which is then available to the bacteria to produce acid.

It is our experience that in wet, low sugar conditions when conditions are really difficult these products will produce better results than most other products available.

Ultra-Sile Arable, Ultra-Sile Dry, Ultra-Sile HiDri and Ultra-Sile Maize are all designed to cope with higher dry matter forages more effectively than lactic only products. The additives have been shown to be effective in preventing heating over a very wide range of dry matter levels. As well as being generally both more effective and more cost effective than chemical preservatives in high dry matter silages, these products are equally effective in preserving low dry matter forages.

Conventional inoculants were designed to treat wet silages produced in the 1980's and were based on homo-lactic bacteria which produced lactic acid only. The aim was to prevent a butyric fermentation on wet, high nitrogen, dirty silage rather than to prevent dryer silages from heating. Lactic acid is easily broken down by the spoilage organisms which cause the heating in dryer silages.

Ultra-Sile

high dry matter additives are capable of producing

a range of acids and anti-microbials including acetic acid and propionic acid and diacetyl rather than lactic acid

alone.

Ultra-Sile

high dry matter additives are capable of producing

a range of acids and anti-microbials including acetic acid and propionic acid and diacetyl rather than lactic acid

alone.

Acetic acid (Vinegar) and propionic acid (Propcorn) have been widely used for generations for preserving food in the kitchen and rolled cereals on the farm because of their toxicity to yeasts, moulds and spoilage organisms. These acids are far more effective than lactic acid at preventing heating and spoilage on dryer silages over 25% DM.

More and more UK dairy farmers are seeing the benefits of using an inoculant which gives improved aerobic stability and reduces heating in the clamp. Ultra-Sile Dry, Ultra-Sile Maize and Ultra-Sile Arable have been shown to reduce yeast and mould contamination in high dry matter silages by up to 99%.

Better quality silage with less heating both on the silage face and in the TMR usually result in better dry matter intakes and improved milk yields. Reduced mycotoxin levels and improved energy intakes can also result in improved health and fertility in the cows.

Ultra-Sile silage additives are designed for maximum nutritional benefit to the

cow,

for proven reliability and for maximum profit for the farmer

Ultra-Sile Dual Action and Ultra-Sile Liquid Combined give an alternative approach to preserving high dry matter forages. These products which use liquid or dry soluble food preservatives such as sodium nitrite or potassium sorbate in combination with a powerful bacterial inoculant offer a particularly effective solution as an alternative to using an inoculant only product.

The Ultra-Sile Range of silage additives is a high tech, state of the art, new specialist range of forage additives. Ultra-Sile Dry, Ultra-Sile Rapid, Ultra-Sile AD, Ultra-Sile HiDri, Ultra-Sile Arable, Ultra-Sile Maize, Ultra-Sile Dual Action and Ultra-Sile Liquid Combined.

At

last UK dairy farmers have access to a range of silage additives which not only produces a

fast, efficient silage fermentation but also results in a forage with excellent aerobic face stability.

At

last UK dairy farmers have access to a range of silage additives which not only produces a

fast, efficient silage fermentation but also results in a forage with excellent aerobic face stability.

A safe, cost effective, biological solution to the problem of heating and spoilage in silage clamps. Not only do these products reduce the risk of mycotoxins, but by preventing heating they reduce losses of valuable sugars and other nutrients from the forage.

The result is more silage and better quality silage with will keep better for longer. Improving the quality of silage reduces concentrate costs and increases milk output.

Ultra-Sile forage additives are extremely cost effective

Typically silage additive treatment costs around 3p - 5p per cow per day. This is an extremely small price compared with potential saving due to reduced clamp losses of up to 5% and milk yield responses of up to 1.5 litres of milk per cow per day.

The Ultra-Sile range of silage additives offer major advances

in terms of

efficiency, ease of use and aerobic stability

Ultra-Sile

biological Silage Additives are supplied in sachets for easy mixing with water for liquid application

using a conventional applicator at between 0.2 and 2.0 litres per tonne of forage.

Ultra-Sile

biological Silage Additives are supplied in sachets for easy mixing with water for liquid application

using a conventional applicator at between 0.2 and 2.0 litres per tonne of forage.

If necessary Ultra-Sile can be applied at lower rates down to 80ml/tonne of forage making the standard product suitable for some ultra low volume applicators. Alternatively Ultra-Sile additives can be supplied in ULV sachets for application at rates down to 20ml/tonne or in bottles for application at down to 10ml/tonne.

Ultra-Sile is also available in granular form in 20kg bags for use in granular additive applicators.

For more information about additives and silage conservation visit our Silage Additives FAQ page.

Alternatively download the Ultra-Sile Silage Additive UK Leaflet

All the active ingredients used in the Ultra-Sile silage additive range have been fully trialled and have EU registration as silage additives under EU1831(2003).

Silage Additives can reduce the overall cost of production of milk

For maximum profitability all conserved forage should be treated with

an effective silage additive as a matter of course

Contact Richard Webster now to discuss which is the best silage additive for your own silage.

Improved forage conservation techniques can have a dramatic effect on the overall profitability of your dairy farm business